Outsourcing CAD engineering services enhances manufacturing efficiency by streamlining design processes, reducing errors, and accelerating time-to-market. CAD outsourcing provides access to skilled professionals, advanced technology, and design automation, leading to improved product quality, cost savings, and a competitive advantage.

info@truecadd.com

How Outsourcing CAD Engineering Enhances Manufacturing Efficiency

Table of Contents

- Why CAD Engineering is Critical for Manufacturing Efficiency

- How Outsourcing CAD Engineering Enhances Manufacturing Processes

- Key Benefits of Outsourcing CAD Services for Manufacturing

- Common Misconceptions about Outsourcing CAD Services

- Choosing the Right CAD Engineering Partner: Key Considerations

- Future of Manufacturing: The Role of Outsourced CAD Engineering

- FAQs related to Outsourcing CAD Engineering

- Wrapping Up

Manufacturers frequently face bottlenecks in their design processes, resulting in delays and budget overruns. An outsourcing CAD engineering company offers a powerful strategy to enhance manufacturing efficiencies. By collaborating with specialized partners, companies gain access to a wealth of experienced engineers and latest technologies, often more cost-effectively than maintaining an in-house team.

This strategic move streamlines design processes, minimizes errors, and elevates product quality. The external CAD engineering team dedicates their full attention to design development, freeing up internal resources to focus on core strengths. This translates to accelerated time-to-market, reduced production expenses, and ultimately, heightened manufacturing efficiency.

Why CAD Engineering is Critical for Manufacturing Efficiency

Computer-aided design (CAD) helps increase manufacturing efficiency by enabling the creation of precise 3D models, facilitating design iterations, and supporting simulations for optimizing manufacturing processes.

Digital prototyping with CAD eliminates the need for expensive physical models and enables us to spot errors early in the design phase. This minimizes material waste and rework, shortens lead times, and reduces production costs.

CAD data seamlessly integrates with computer-aided manufacturing (CAM) systems, creating a streamlined path from design to production and facilitating automation on the shop floor. This integration minimizes the risk of errors from manual data transfer and ensures manufacturing accuracy.

How Outsourcing CAD Engineering Enhances Manufacturing Processes

Outsourcing CAD engineering presents a strategic advantage that can reshape how you approach manufacturing.

Here are a few ways in which it helps transform your manufacturing process:

- Accelerated product development: CAD engineering firms specialize in rapid design iterations, allowing you to compress product development timelines significantly. By partnering with external experts, you bypass the lengthy process of building an internal CAD team, resulting in faster time-to-market.

- Access to advanced technology and skills: Outsourcing provides immediate access to the latest design software and specialized knowledge without requiring significant upfront investment. This keeps you at the forefront of innovation, enabling you to leverage advanced design capabilities for enhanced product performance.

- Streamlined communication and project management: Established CAD engineering firms employ proven communication and project management methodologies. This ensures efficient collaboration and information exchange, minimizing misunderstandings and ensuring smooth project execution and on-time delivery.

- Flexibility & scalability: Outsourcing CAD engineering allows you to scale resources dynamically, aligning with project needs. You can access additional expertise during peak periods and scale back when demands are lower, optimizing resource allocation and cost-efficiency.

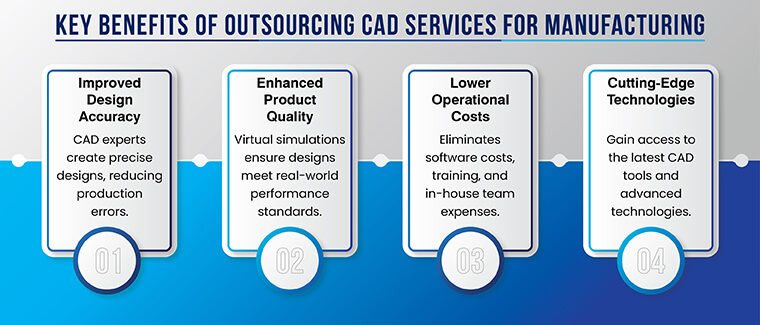

Key Benefits of Outsourcing CAD Services for Manufacturing

Outsourcing CAD is a strategic move that empowers manufacturers to optimize production and drive down costs.

Following are the key CAD outsourcing advantages:

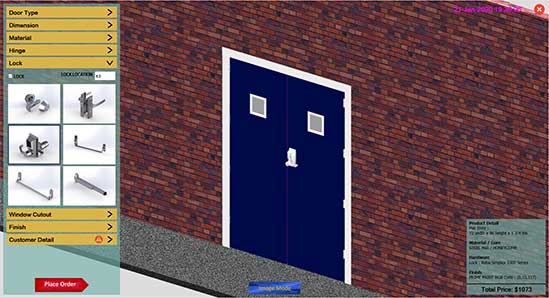

Design Automation for Streamlined Production

Outsourcing CAD engineering design services allows manufacturing companies to leverage design automation for smoother production. Specialized CAD outsourcing firms excel in using software like SolidWorks and DriveWorks’ design automation technology to optimize the design process. They can create standardized design templates and automated workflows, which reduce manual work and minimize errors.

Manufacturers achieve faster design cycles and shorter lead times by automating repetitive design tasks and streamlining product configuration. This streamlined approach ensures that manufacturing can begin quickly after design completion, reducing downtime and optimizing production schedules.

Success Story: Metal Doors & Frame Design Customization using DriveWorks

A hollow door manufacturer supplying doors to healthcare industry and government projects in the US partnered with TrueCADD’s DriveWorks automation team. The design automation engineers developed product configurator for custom door design and deployed it online.

The partnership resulted in:

- Reduction of engineering lead time from 4-5 days to a few hours

- Increase in quality of deliverables up to 99%

- Reduced engineering cycle time by 70%

Online Configurator for Metal Door

Online Configurator for Metal Door

3D Door Components Customization

3D Door Components Customization

Get design automation to reduce design cycle time by 70%.

Implement now »Better Product Design and Faster Prototyping

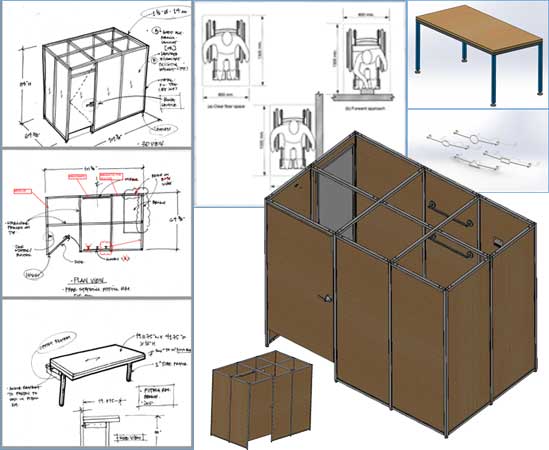

An outsourcing CAD engineering company helps produce positive downstream effects on product design and prototyping cycles. Companies with in-house engineering teams benefit from accessing a wider talent pool with niche expertise without the overhead of recruitment and training.

CAD drafting for manufacturing with access to this talent pool helps create high quality 3D models, facilitating more efficient communication and collaboration between design and manufacturing teams.

The use of advanced CAD software by these firms enables the creation of virtual prototypes, allowing for design iterations and simulations to be conducted in a digital environment. These virtual design and construction services reduce the reliance on physical prototypes, resulting in significant cost and time savings during product development.

The accelerated iteration process inherently leads to faster design finalization and, consequently, quicker turnaround times for prototypes.

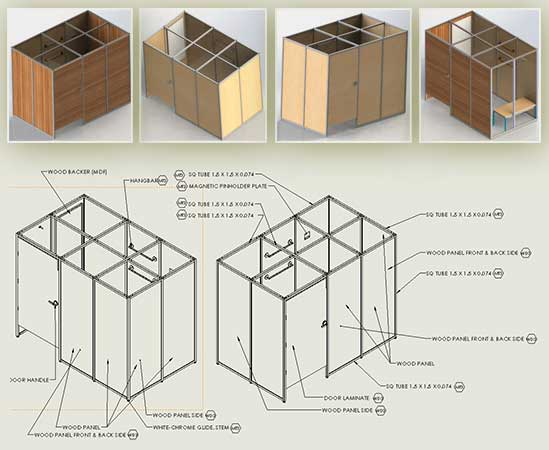

Success Story: Detailed CAD Drawings & 3D Models for Retail Furniture Manufacturer

TrueCADD delivered detailed CAD drawings and 3D models for a retail furniture manufacturer in the UK. Starting from hand-drawn sketches, TrueCADD transformed concepts into precise manufacturing designs, ensuring efficient production of retail furniture, including fitting rooms and store fixtures.

The client was able to achieve:

- On time delivery of drawings

- Detailed documentation for site assembly & installation assistance

- 70% overall project cost saving

Concept Drawings to CAD Detail Design

Concept Drawings to CAD Detail Design

3D Models and Manufacturing Drawings for Retail Store Fitting Room

3D Models and Manufacturing Drawings for Retail Store Fitting Room

Take the next step toward optimized manufacturing.

Contact our experts »Simulation-Driven Design for Reduced Testing Costs

Simulation-driven design enables you to move beyond the limitations of physical prototypes. CAD software helps us construct detailed virtual models and expose them to a range of simulated conditions – stress, temperature gradients, vibrational loads – all within a controlled digital environment.

This is crucial for identifying potential weaknesses early in the design process. For example, while designing a turbine blade, through simulation, we can analyze the blade’s response to high temperatures and centrifugal forces. This helps in predicting potential fatigue points or stress fractures long before manufacturing physical prototype.

This reduces costly and time-consuming physical testing and facilitates a more iterative and refined design process. Also, by virtually experimenting with different materials, geometries, and load conditions in CAD, we optimize the designs for performance, durability, and safety, ultimately leading to more robust and efficient end products.

Common Misconceptions about Outsourcing CAD Services

While the role of CAD outsourcing in production efficiency offers numerous advantages, some manufacturers hesitate due to persistent misconceptions.

Let’s dispel a few of these myths:

Myth 1: Outsourced CAD work is of inferior quality.

Specialized CAD outsourcing firms employ seasoned drafters and engineers who excel in industry-standard software and adhere to international design codes. Robust project management tools and clear communication channels ensure accurate translation of design intent, maintaining high quality and adherence to specifications.

Myth 2: Outsourcing leads to loss of control over the project.

Successful outsourcing is rooted in collaboration. Transparent communication protocols, regular progress updates, and collaborative platforms facilitate real-time feedback and revisions, keeping projects aligned with their goals. Clients retain control over design decisions while leveraging the expertise of their outsourcing partner.

Myth 3: Outsourcing is only suitable for large-scale projects.

While large corporations frequently utilize outsourcing, the scalability of CAD services benefits smaller firms as well. Whether it’s designing a single component or a complex assembly, outsourcing provides access to specialized skills and software without the overhead costs, making it a cost-effective solution for projects of all sizes.

Myth 4: Intellectual property (IP) security is compromised when outsourcing.

Reputable CAD outsourcing firms understand the critical importance of IP protection. Non-disclosure agreements (NDAs) are standard practice, safeguarding sensitive design data. Additionally, secure data transfer protocols and access control measures minimize the risk of unauthorized access or breaches, ensuring your IP remains protected.

Choosing the Right CAD Engineering Partner: Key Considerations

When you are integrating an outsourced CAD engineering team into your manufacturing workflow, choosing the right partner is crucial. A poor choice can disrupt your project timelines, create communication bottlenecks, and ultimately undermine the efficiency you are striving for.

Here is a breakdown of the key factors to guide your decision:

Reputation and Experience

Don’t just rely on marketing materials; investigate the firm’s actual track record. Look for case studies that demonstrate their success in your specific industry. Client testimonials and online reviews provide valuable insights into their reliability, their ability to meet deadlines, and their problem-solving skills.

Expertise in CAD Software

Ensure the potential partner has engineers who are demonstrably proficient in the exact CAD platforms your projects require. This goes beyond basic skills; they need a deep understanding of CAD engineering for manufacturing optimization, advanced features, customization options, and compatibility nuances.

Communication and Project Management

Effective communication is essential for seamless integration. Evaluate the firm’s communication protocols, preferred channels, and responsiveness. Do they proactively provide updates, or do you have to chase them down? A well-defined workflow, ideally using collaborative platforms and version control systems, promotes transparency and efficient iteration.

Data Security and Confidentiality

Manufacturing designs often contain sensitive information and intellectual property. Scrutinize the firm’s data security measures. Do they have strong cybersecurity protocols in place? Are their data storage solutions compliant with industry regulations? A legally binding non-disclosure agreement is essential to protect your designs and trade secrets.

Future of Manufacturing: The Role of Outsourced CAD Engineering

The future of manufacturing is intrinsically linked to outsourced CAD engineering companies and the technologies they wield.

CAD design services for manufacturing are adept at optimizing designs for 3D printing processes, ensuring manufacturability, minimizing material usage, and reducing lead times. They leverage topology optimization and generative design software to further refine these benefits.

These firms are also rapidly integrating AI into their workflows, utilizing machine learning algorithms for generative design. This empowers AI to explore countless design iterations based on specified constraints, ultimately leading to innovative solutions and optimized performance.

The data-rich environment of smart factories offers outsourced CAD companies a crucial role. They provide digital twins of products and processes, allowing for simulation and analysis. This in turn facilitates improved production planning, predictive maintenance, and real-time decision-making.

FAQs related to Outsourcing CAD Engineering

-

Outsourcing CAD engineering grants you access to a pool of skilled professionals, allowing you to cut down on costs while ensuring design accuracy and faster production timelines.

-

Yes. Outsourcing eliminates the need to invest in costly software, extensive training programs, and maintaining an in-house team, all while delivering high-quality designs.

-

Outsourced CAD teams specialize in creating precise, simulation-driven designs. This translates to improved product quality and a significant reduction in the likelihood of manufacturing errors.

-

Design automation streamlines the design process by automating repetitive tasks. This accelerates the entire process and allows for swift adjustments, ultimately boosting overall efficiency.

-

When selecting a CAD partner, prioritize their industry experience, expertise in the relevant software, and robust communication and project management skills. These factors are crucial for a successful collaboration.

Wrapping Up

An outsourcing CAD engineering company is no longer just an option—it’s a strategic necessity if you’re looking to boost efficiency and stay ahead of the competition. By leveraging external expertise and adopting technologies like design automation and simulation-driven design, your company can drastically cut down lead times, streamline costs, and elevate product quality.

CAD/CAM outsourcing benefits enable you to free up your internal resources, allowing you to focus on what you do best and drive innovation that fuels sustainable growth. In today’s fiercely competitive market, outsourcing CAD engineering is a transformative step towards achieving manufacturing success.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.