CAD tools for Design for Manufacturing (DFM) strategies not only enhance the aesthetics of sheet metal products but also mechanical integrity by streamlining the manufacturing processes. They help manufacturers to significantly reduce engineering lead times, lower production costs, and maintain a competitive edge in a thriving market.

info@truecadd.com

Enhancing the Efficiency in Sheet Metal Doors and Windows Design

The market for metal doors and windows is growing at a CAGR of 5.7% from 2022 to 2032. While this forecast is promising, manufacturers need to enhance their design and manufacturing processes. Only the adoption of sophisticated design tools with integrated automation capabilities can ensure that sheet metal design for doors and windows meets the needs of this competitive market.

The US accounts for over 60.0% of the revenue share of the North American sheet metal market. To keep in step, it’s imperative to refine your sheet metal design and fabrication techniques. This includes mastering the use of advanced CAD tools and DFM strategies, which ensure that products are not only aesthetically pleasing but also mechanically sound and easy to manufacture. By focusing on these areas, your team can reduce the engineering lead time significantly, from several days to same-day turnaround, without compromising quality.

Table of Contents

Why Focus on Sheet Metal Door and Window Design?

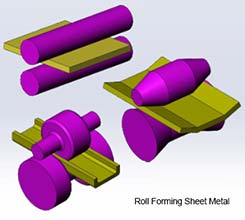

A detailed understanding of sheet metal properties and Design for Manufacturing (DFM) considerations for door and window design is crucial. For instance, knowing the appropriate minimum bending radius, which depends on the metal grade used, can prevent issues like improper fits and operational inefficiencies. Moreover, innovative fabrication techniques, such as roll forming and the strategic use of grooves and ribs, can enhance the structural integrity and functionality of the final product.

Key Design Considerations in Design Drafting of Sheet Metal Doors/Windows

Sheet Metal Design Using DFM (Design for Manufacturing) Strategy

One of the major concerns while designing doors and windows is the lack of a designer’s knowledge of sheet metal design. Unlike solids, sheet metal design involves a sound understanding of the physics and manufacturability, as sheet metal parts behave differently in a real-world environment.

The following are some of the key sheet metal design considerations a good designer should know to maintain the design intent and maximize manufacturing efficiency:

Minimum Bending Radius

Fig. 1

Fig. 1

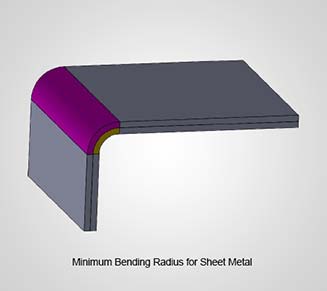

The bending radius is critical when considering door and window designs, and it varies depending on the grade of sheet metal used. The frames and plinth of metal doors and windows are an excellent example of section profiles that use the bending process.

Insufficient bending radius on these components compromises the flatness of the rabbet on which the door will actually rest. This leads to further inaccuracies in installing and operating the door.

As a rule of thumb, the minimum bending radius for a mild steel sheet metal should be equal to the thickness of the sheet.

Fig. 2

Fig. 2

Bending radius also depends on the type of brake tool used. The frames for doors and windows usually employ a roll-forming method for bending. (See fig.1) Bending the sheet to a designer-specified bend angle may lead to spring-back effect – a tendency of the sheet metal to retain its original flat form. This happens because the top surface of the sheet undergoes tension, and the bottom one is under compression.

This is why the brake operator will overbend to the bending angle, so that the desired bent angle is achieved once the part is released from the pressure.

In sum: The designer must predict and efficiently account for the springback while developing the designs for doors and windows to avoid change orders later during the manufacturing stage. It will not only ensure seamless and optimized design process but enhance overall manufacturing efficiency.

Find out how optimal is your bending radius.

Talk to an expert »Grooves, Ribs, and Holes

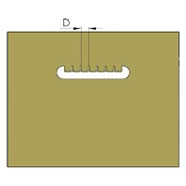

Fig. 3

Fig. 3

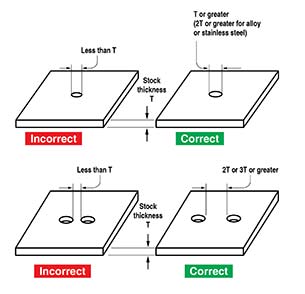

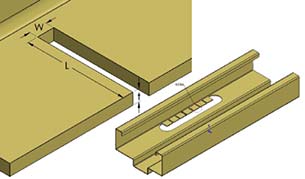

While holes are important for fastening metal doors and windows using hinges, they also do the job of imparting strength to the formed part. The metal around the area where holes are punched or drilled gets stretched and becomes more tensile, providing better structural rigidity to the sheet. However, the size of the hole and the distance between the two holes are important to consider before punching or drilling them out. (see Fig. 3)

As a thumb rule, the hole diameter should not be less than the sheet thickness, and the distance between the two holes must be at least two times the sheet’s thickness. The diameter goes up to two times the thickness of the sheet for stainless steel or alloy material.

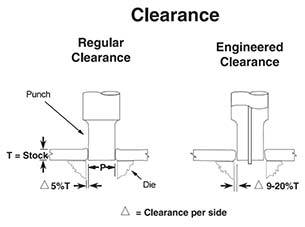

Maintaining the hole diameter-to-stock thickness ratio is important, as punching holes that are smaller than the material thickness causes the stamping forces to spread out instead of going downwards through the material. (See Fig. 4.)

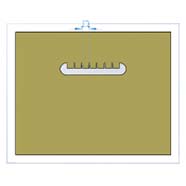

Fig. 4

Fig. 4

When this ratio is not followed, the punch often gets stuck in the material and, in many cases, deforms the part altogether. Ultimately, this results in an increase in cost per run and demands more maintenance, further delaying the fabrication process.

However, in the case of metal door frames and doors design, there is a need to punch smaller holes to accommodate fastening the locks and hardware items. In such situations, holes are usually produced through drilling or machining processes.

Grooves and ribs offer additional strength without adding to the wall thickness and are often used in doors and windows to offer tight weather seals between sections. It enhances the overall fabrication efficiency of doors by focusing on easing out the punching process.

In sum: The designer needs to consider keeping a provision for these elements early during the design stage to reduce the possibility of errors during the punching process.

Get the right DFM strategy for your sheet metal doors.

Request a proposal »Notches and Tabs

Fig. 5

Fig. 5

Sheet metal doors and windows need notches and tabs to make provisions for hinges and locks. But there are a few design parameters to consider when specifying the notch. (see Fig. 5)

The rule of thumb here is that the notch width shouldn’t be narrower than 1.5 times and the length should be a maximum of 5 times the sheet thickness.

In sum: The designer needs to consider that the minimum distance between a bend and a notch should be 3 times the material thickness plus the inside bend radius. And, when there are two notches, the space between them should not be less than 2 times the sheet’s thickness.

Fig. 6 Wrong method

Fig. 6 Wrong method

Fig. 7 Right method

Fig. 7 Right method

Fig. 8

Fig. 8

Fig. 9

Fig. 9

Minimum Flange Width

Flanges are often useful in reinforcing the tops and bottoms of doors with inverted horizontal channels. Reveal flange, for example, is an essential part of the door frame profile that extends from the return and forms parallel to the wall.

In sum: The designer needs to consider that the minimum height of a bent flange should be proportional to the material thickness, bend radius, and length of the bend. The minimum width of a bend relief should at least be equal to the material thickness, or 1.50 mm, whichever is greater.

Welding Alternatives

Welding is an ideal solution to join two parts of the material together, but a more important question one needs to ask here is whether it is necessary to weld or if fasteners can do the job. Removing the welding process helps reduce manufacturing costs considerably.

For example, making use of knockdown metal door jambs instead of welded ones can reduce the need for welding processes to a certain extent. However, these types of jambs are often suitable when the interior walls are finished with drywall or plaster.

Simple modifications in the design, such as extending the bracket from the base material instead of attaching it separately, can eliminate welds and bring about significant cost reductions.

In sum: The designer must consider the available bending technology on the shop floor before redesigning the part without welds.

CAD Design Tools for Sheet Metal Doors and Windows Design

While these design tips ensure better efficiency for you in manufacturing doors and windows, achieving these results requires the right technology tools that support the DFM strategy and offer you, as the designer, the flexibility to quickly design sheet metal parts and generate fabrication drawings for the shop floor.

Popular 3D parametric CAD tools such as SolidWorks and Autodesk Inventor® offer an array of features for designers to easily develop sheet metal parts with accurate forming and welding details. The tool automatically generates flat patterns with bend compensation, pushing the design to your production faster.

Whether you’re working on sheet metal doors, windows, or other complex assemblies, SolidWorks provides the tools necessary to achieve high-quality results. SolidWorks sheet metal modeling has dedicated sheet metal modules to create sheet metal SolidWorks drafting.

Don’t have the right CAD tool for design? Relax, we have got you covered.

Contact Us »Integrating Design Automation in Sheet Metal Door and Window Design

What follows, adopting a 3D sheet metal design tool, is the ability to automate repetitive design tasks. The benefits of design automation are evident when designing custom sheet metal doors and windows that are specific to building requirements. From the automatic generation of 3D models and flat patterns to cut lists and fabrication drawings, automation significantly shrinks the design cycle.

Tools like DriveWorks for SolidWorks and iLogic for Inventor take automation to the next level by offering the opportunity to develop sales configurator for doors and windows. Such configurators promote guided selling, where a customer simply inputs the sizes and configurations as per his/her requirements and the 3D model, along with an estimated cost, is displayed upfront.

Metal door manufacturer speeds up design cycle by 70% using design automation.

TrueCADD helped a leading US-based manufacturer of custom hollow metal doors reduce the design cycle by 70% by implementing design automation and product configurators using SolidWorks and DriveWorks. The engineering lead time was reduced from a 4-5-day turnaround to same-day engineering and manufacturing.

Final Word

As the demand for sheet metal doors and windows goes up, manufacturers must embrace advanced design and strategies to stay competitive. By integrating the right design principles, CAD tools, and design automation technologies, manufacturers can deliver higher product quality, faster customization, and reduced costs. Embracing these innovations will not only streamline production processes but also boost profitability and give you a competitive advantage.

Touch new heights for your door-window design.

Get a free quote now »Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.