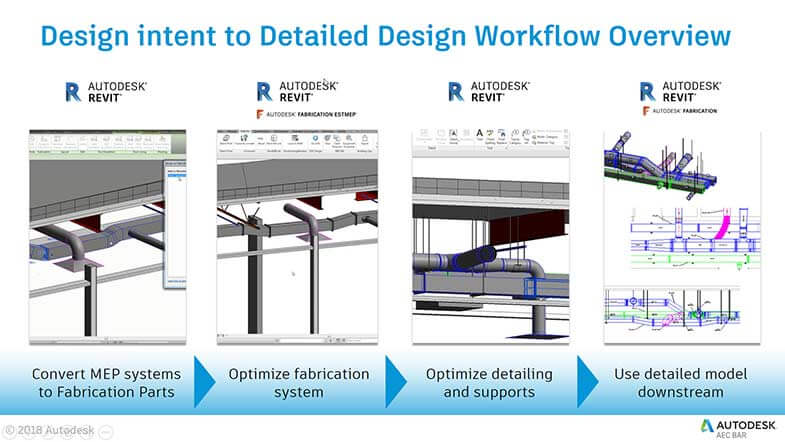

MEP shop drawings drive accurate fabrication and installation through precise and detailed information and advanced visualization that clearly communicate design intent. Extraction of detailed drawings from Revit®, for each MEP component, ramps up project speed and streamlines construction.

info@truecadd.com

What are the Benefits of MEP Shop Drawings for Building Contractors?

In an extremely competitive construction market, delays, budget overshoots and quality compromises can cripple project efficiencies and ROIs. MEP contractors must ensure seamless and true to design fabrication and installation of every MEPF component – be it mechanical, electrical, plumbing, or fire protection.

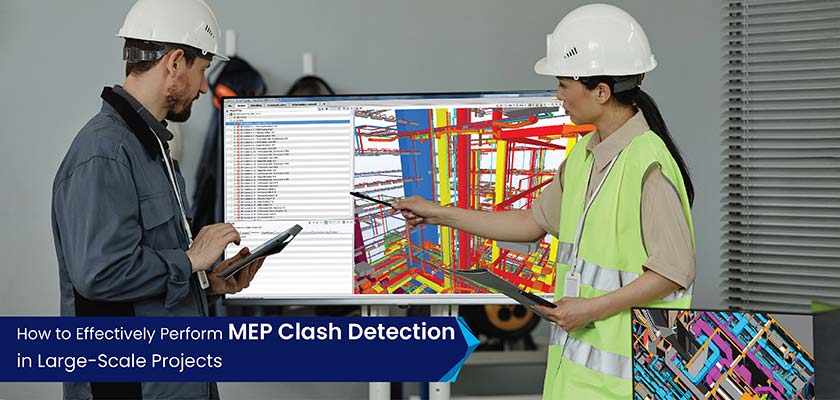

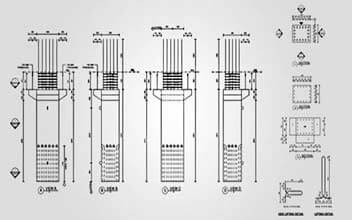

Spatially coordinated MEP shop drawings with granular details related to dimensions, design specifications and standards help onsite teams execute as-is design intent. The detailing and cross functional visualization enable clash-free fabrication and MEP component installation.

MEP shop drawings extracted from Revit models also facilitate ease of coordination of contractors with suppliers, fabricators and manufacturers for MEP installations. The finer component-level detailing they provide related to turning, bending, welding, assembling, etc. help accurate and safe fabrication. Through minimal iterations, they ensure on time project completion and controlled costs.

In this blog we discuss the challenges faced by building contractors with legacy processes and the advantages of MEP shop drawings for them.

The MEP challenges faced by building contractors

- Lack of details in design drawings lead to inaccurate component installation

- Lack of project visualization hampers informed decisions

- Absence of detailed information results in inaccurate budget forecasting

- CAD-based drawings or sketches do not allow fabrication standardization

- Low collaboration between stakeholders due to workflow silos

Opening up walls or ceilings to install connections or relocating equipment at a later stage could cause costly rework. MEP shop drawings effectively minimize this by enabling higher first time right MEP installations.

Benefits of MEP shop drawings for building contractors

Accurate component installation with model-based MEP shop drawings

Extraction of accurate and information-packed MEP shop drawings from coordinated and clash-free Revit 3D BIM models assists contractors with precise MEP installation. With every MEP component, detailed, annotated and tagged for representation and final assembly, contractors can visualize MEP components from every angle. Step-by-step directions, exhaustive material lists, etc. guide contractors to achieve hassle-free installation.

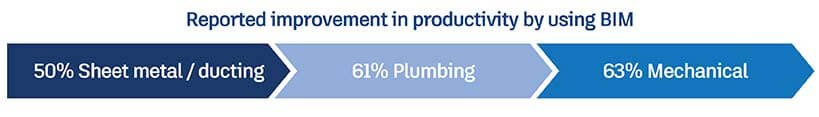

MEP shop drawings extracted from BIM models help manufacturers and fabricators in error-free fabrication and installation of MEP components at an offsite location. With every dimension, material specification, and other information mentioned accurately, fabricators can manufacture MEP components. General contractors can capitalize on this capability to reduce onsite installation time and lower project costs leading to an improved overall project ROI.

Better design intent and visualization

Design objectives are crucial details that require attention in the early design stage or preconstruction stage. Clear visualization of an MEP layout and components through standardized codes creates a better standpoint for MEP engineers and specialists to gain greater control over project design.

Coordinated MEP shop drawings catch discrepancies before they occur on site by leveraging dimensional accuracy of fabricated components. This ensure seamless installations and promotes enhances constructability.

Efficient budget planning with detailed information about MEP components

Accurate accounting of MEP components or systems for large-scale and complex construction projects is a core requirement for effective and efficient cost planning. General contractors face a series of challenges when it comes to presenting accurate MEP component budgets. MEP shop drawings are an excellent source of information to precisely determine the cost of materials needed for fabrication.

Preventing material wastage is a decisive factor to optimize costs. Overspending on materials can lead to project costs going over budget, or underspending on inferior materials can compromise building quality. Efficient cost planning is supported by accurate scheduling of MEP components onsite. Getting logistics to comply with building schedules enriched with walkthrough sequencing diminishes workflow clashes leading to quick and transparent MEP installation.

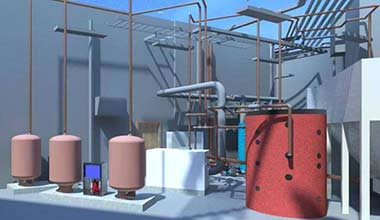

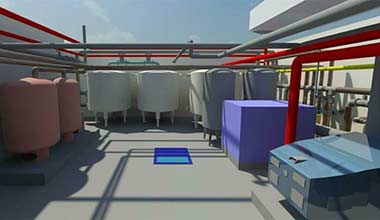

Detailed MEP shop drawings drive cost savings for European plant room project

A European BIM consultant approached TrueCADD for Revit models with detailed MEP shop drawings for a plant room. The input files shared included 2D files and manufacturing details of MEP equipment.

The clash-free 3D MEP model and shop drawings generated for the plant room layout drove informed decision-making on the project as well as saved on costs.

Standardize products with Revit MEP libraries

An exhaustive data-set of Revit MEP libraries for modeling and 2D shop drawings draws better accuracy reinforced with project specifications. System and loadable Revit families for HVAC, electrical, plumbing, and fire-fighting components make shop drawings:

- Technically accurate

- Scalable and flexible

- Dimensionally verifiable

- Coordinated

Customized MEP Revit libraries simulate real-world functions and ensure high quality and quick turnaround within projected costs. With complete metadata and product literature that includes technical datasheets, industry standards like COBie, model type, etc. fabricators and building contractors can collaborate effectively and efficiently.

Better collaboration with integrated workflows via MEP BIM models

MEP BIM models are driven by exhaustive collaboration from various trades. A single, coordinated, and clash-free 3D Revit MEP model assists stakeholders with better documentation and construction outcomes. Integrated workflows from an early design make sure general contractors receive accurate and high-quality deliverables to ease the onsite installation of MEP systems.

Integrated MEP workflows save time and cost for an Asian company

An Asian pre-cast manufacturing company required a coordinated Revit structure model for an office building.

The team of experts at TrueCADD delivered a clash-free Revit 3D model at LOD 450 for architectural, structural and MEP disciplines. Detailed construction drawings extracted from the MEP model promoted better collaboration and ensured streamlined installation and fabrication. The first time right installations, reduced material waste and timely deliveries increased project efficiency.

The future – Use of robotics in MEP drawings

BIM-embedded construction robots can handle mundane or dangerous tasks, improving safety increasing performance on the construction site. The Building information model data could be used as a map for the robots working on site. It can be operated with minimal assistance and supervision and mitigate the risk of expensive errors.

Robotic Total Stations (RTS) and handheld devices like smartphones or tablets can be used to accurately pinpoint hanger positions through lasers. Using 3D visualization, points can be identified and marked. Operators are given directions of the distance between various points to mark points and move ahead. Lasers precisely pointing locations saves on rework and diminishes project delays.

Some of the benefits of robotic-driven MEP drawings and workflows include:

- Better efficiency

- Quick collaboration using a unified model and drawings

- Optimized recording and documentation of layout points

- Reduction in paperwork

- Lower operator costs with improved productivity

- Enhanced quality control

A combo of Robots can also be used to report from the field to the project office via cloud computing resulting in increased productivity within budget and schedule.

Conclusion

MEP shop drawings serve as another set of eyes for building contractors to streamline fabrication and onsite installation as they precisely document design intent. However, it is imperative, that contractors seek specialists to create MEP coordination drawings that can help save on rework.

Serving as a basis, before actual construction starts, shop drawings can overcome complex challenges to derive an effective and efficient build procedure. Laying out a sound MEP system that works in sync with the structure, without interfering with one another helps contractors and stakeholders build strong, sustainable buildings and improve construction efficiencies.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.

Partner with us for your BIM modeling needs →

Partner with us for your BIM modeling needs →