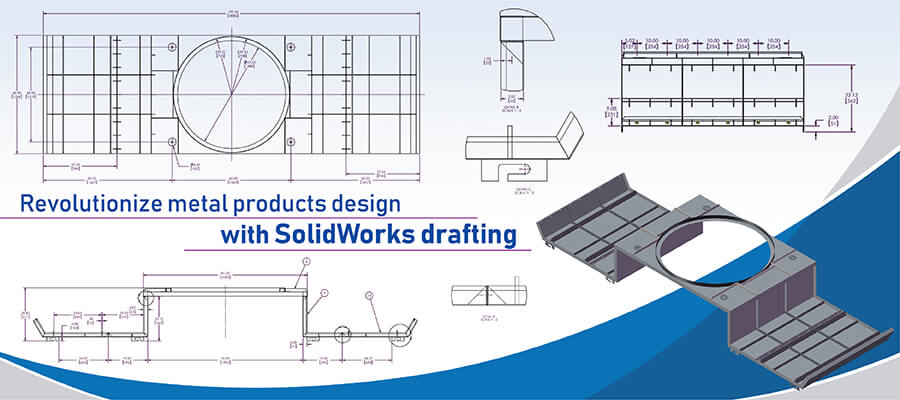

SolidWorks is a proven CAD platform for creating sheet metal design drawings with a lot of design detailing. SolidWorks drafting, with a range of features and functions, addresses the challenges of personalization, reduce engineering design time, optimize quality and hep conformity to design standards.

info@truecadd.com

Why You Should Consider SolidWorks Drafting in Metal Products Design

The efficiency of sheet metal fabrication projects lies in the preciseness of the design briefing by the CAD shop. With increasing personalization of products, design briefs get more detailed and specific. The final designs hence go through a series of iterative processes before being released to the machine shop.

2D drafting is extremely time-consuming and inept at handling this level of design detailing and specificity. This is where 3D CAD platforms play a critical role.

Source: Partsolutions.com

Source: Partsolutions.com

With speed, flexibility, and precision in design drafting, 3D offers a winning edge to small and medium-sized sheet metal fabricators. Parametric features and sheet metal modeling in SolidWorks reduce iterations to accelerate design development. They also factor in shop floor processes to develop design drafting seamlessly.

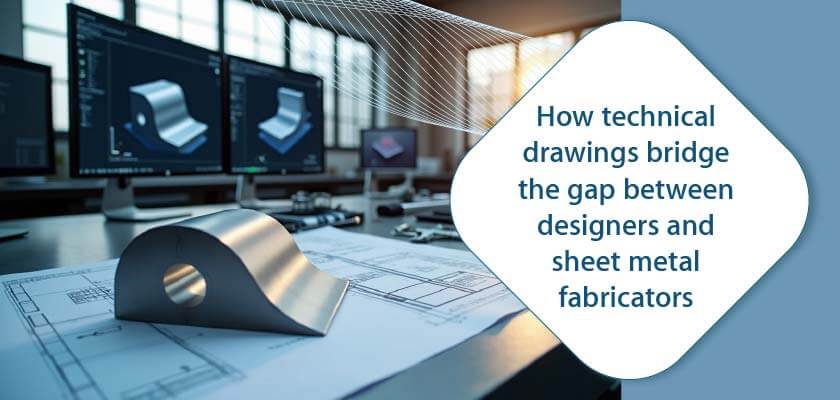

Challenges for sheet metal fabricators

Creating great design and drawings call for multiple skills, a knowledge bank of manufacturing processes and materials, a need for cost consciousness, and a brief of manufacturing capabilities. A sheet metal designer, thus wears multiple hats to deliver optimized, manufacturable and robust designs that are consistent with fabrication methods and operational conditions.

Some of the challenges that SME sector manufacturers face:

- Creating error-free models with sheet metal features and DFM guidelines

- CAM integration with PLM or cloud technology in CAD for cost effective solutions

- Capturing DFM needs and freeform development with complex CAD software architecture

SolidWorks offers a good fitment covering end-to-end drafting needs right from concept development to detailed technical drafting. It has a set of tools dedicated to sheet metal design drafting that can help create parts with ease.

How SolidWorks revolutionizes sheet metal design and drafting

Let’s look at some of the benefits of using SolidWorks specifically for sheet metal design and drafting:

Flexibility

SolidWorks offers the flexibility to design the part as a 3D model (non-sheet metal) and later convert it into sheet metal to incorporate DFM requirements. The designer can also start with sheet metal directly if the component is simple and all features are well planned.

The order of design preference to be followed while creating sheet metal parts from a 3D model:

- Start with sheet metal as base flange and add up edge flange and miter flange

- With the right ‘K factor’ according to material and thickness, insert bends with the ‘Bend’ feature

- Convert to sheet metal feature

- Create additional features that are needed in your sheet metal designs

Intuitive design

SolidWorks 3D intuitive design for sheet metal gives you the design flexibility to produce sheet metal parts and accurate virtual prototypes. It is important in sheet metal design that designers should plan their design approach.

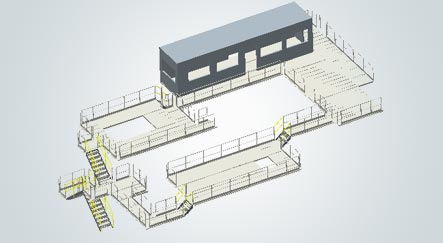

TrueCADD’s sheet metal design experts adopted a flexible top-down approach for 3D modeling and drafting of hoppers and walkway for a recycling plant. It empowered the manufacturer to accelerate engineering cycle and increase deliverables to an average volume of 55 hoppers/month.

User friendly sheet metal modeling features of SolidWorks

Ideally, a single 3D model for sheet metal products should have comprehensive design features to ensure clear design intent communication. For example, a typical sheet metal part model can have more than 20 features. This shows the need for an efficient CAD platform like SolidWorks with specific sheet metal design drafting features.

SolidWorks has provisions to:

- Incorporate various types of flanges like base, edge, miter, and swept

- Incorporate tabs and slots

- Generate basic as well as advanced bends like lofted, sketched, etc.

- Read readily available bend tables for bend allowance and K factors with material properties

- Create forming features like extruded flanges, embosses, louvers, lances, and ribs

- Add weldments to sheet metal parts

Ease in design drafting and modeling

The user-friendly program interface in SolidWorks allows the design engineer to complete the model in a progressive manner with required level of design detailing.

SolidWorks helps designer with:

- Effective design development through conceptualization in 3D

- Importing external CAD models, creating designs around it or a group of parts and converting 3D solid parts into sheet metal parts

- Creating detailed manufacturing drawings while developing 3D models

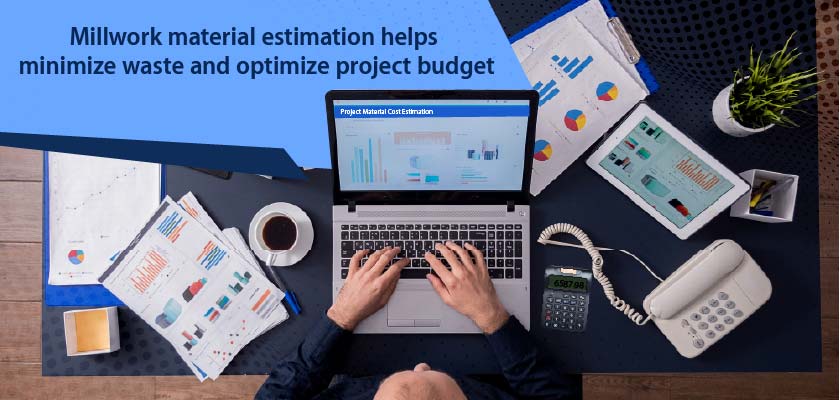

Efficient engineering documentation

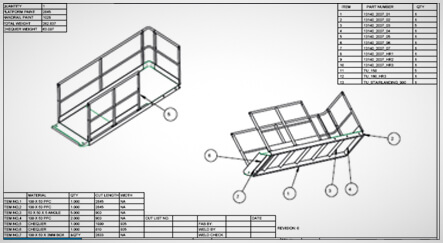

While creating sheet metal parts, the designer needs to perform several technical tasks along with basic 3D sheet metal modeling.

SolidWorks offers:

- Creation of detailed manufacturing drawings from 3D Sheet metal parts and assemblies

- Auto-generation of flatten parts for flat patterns needed during manufacturing

- Estimation of manufacturing costs in real-time while designing

- Ease in updating concurrent drawings as they have bi-directional relationships with 3D models

- Accuracy and precision of engineering drawings by capturing detailed requirements for high-quality metal fabrication

- Ready-to-use component libraries to accelerate designing process

Scalable software architecture

The overall software architecture of 3D CAD SolidWorks is scalable and flexible with many customizable scripts, macros, and plug-ins. It also allows integration of external application, for sales, and manufacturing through APIs. It has a relatively simpler user interface and hence you need minimal training and maintenance.

Using SolidWorks you can:

- Have enhanced look and feel of models with GUIS

- Build and validate virtual prototypes with inbuilt applications

- Maintain high-level of interoperability between applications like CAD/CAM/PLM/CRM/ERP

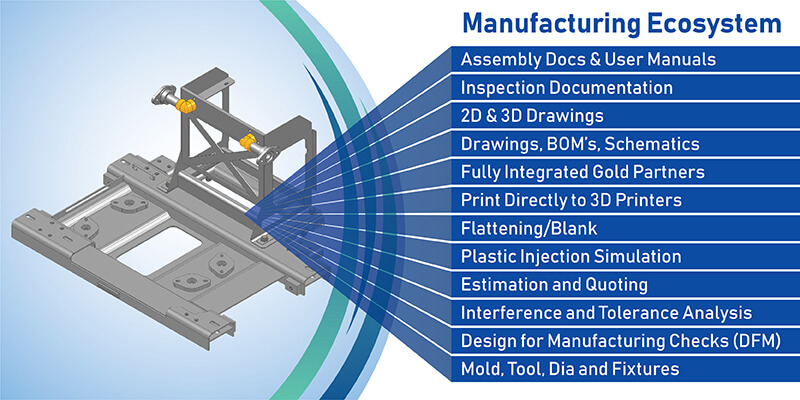

Advanced applications of SolidWorks with design automation

SolidWorks has extended applications that meet the requirements of digital product life cycle and manufacturing ecosystems. It allows companies to go from concept design to prototype and manufacturing faster than ever before.

Source: blogs.solidworks.com

Source: blogs.solidworks.com

3D visualization with a high-level rendering for product marketing and sales

With SolidWorks Visualize, the designer can accurately simulate a real-world environment with lighting and advanced materials. High-level rendering allows 360-degree spins and animation of models in real-time.

All this enhances user experience, sales effectiveness and collaboration across the value chain.

Development of an interactive configurator

SolidWorks with DriveWorks allows designers and manufacturers to create CTO-based product offerings with the help of visual product configurator. Advanced configurators not only incorporate product mix but also automate the workflow from sales order to manufacturing.

This digitizes the manufacturing process. The configurator generates quick documents like quotes, drawings and Bill of Materials (BOM) for sales, manufacturing and supply chain.

Seamless design collaboration of MBD with different teams

Using SolidWorks MBD, the designer can create 3D model and assemblies. These can be used to create 3D drawings with manufacturing specifications.

The embedded information is directly fetched from the model by various users like manufacturing, suppliers, and sales teams. It speeds up manufacturing with accuracy and high-level collaboration.

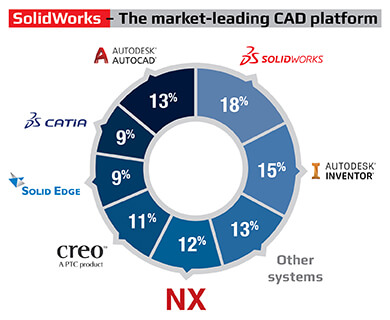

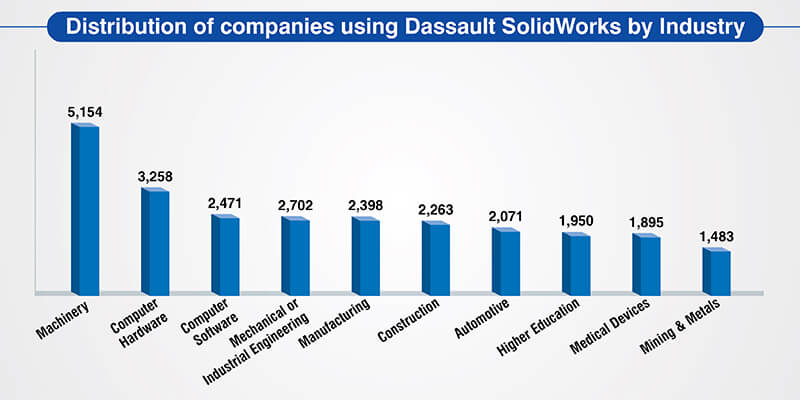

Industry-wise usage of Dassault SolidWorks

Today, more than 6,300,000 product designers and engineers across 300,000 companies use SolidWorks for better tomorrow. It is highly popular among companies having 10-50 employees and 1M-10M US$ in revenue. Here is a breakup of SolidWorks usage by industries in the USA.

Source: Enlyft.com

Source: Enlyft.com

Wrapping Up

With SolidWorks, you can design and create detailed drawings with agility and precision. It remains one of the most widely used and trusted CAD tools for most designers and manufacturers around the world. By teaming up with expert CAD drafters, sheet metal fabricators can make the most of advanced features offered by the tool and remain cost effective.

SolidWorks helps create deliverables for sheet metal detailing that are both, durable and elegant with the inbuilt intelligence of DFM rules. Moreover, with advanced applications like MBD and product configuration of SolidWorks, manufacturers can not only improve the design and manufacturing value chain but also extend the benefits to other functions like sales and marketing.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.