4D BIM is an excellent tool for managing material and resources on the field. The logical sequencing of onsite tasks and accurate budget estimation catalyze the way construction projects are designed, managed and developed.

info@truecadd.com

Types of 4D BIM Construction Scheduling Techniques

Traditional scheduling techniques have multiple challenges and limited benefits though the AEC industry is still comfortable with it. 2D scheduling and bar charts often throw up inaccurate layouts and obscure presentations, hampering informed decisions, delaying projects and adding to costs.

4D BIM’s accurate scheduling and sequencing features backed by visualization and coordination capabilities transforms the way architects, contractors and other stakeholders operate. Optimized construction costs, on time project completion and better interdisciplinary communication are some positive outcomes experienced by BIM users globally.

READ HERE : What does 4D BIM Mean for Your Construction Business?

Why is 4D BIM scheduling important for construction projects?

4D BIM Scheduling is important for construction projects as it helps engineers, designers, estimators and schedulers link 3D models to schedules. It helps leverage the opportunities of real-time scheduling in terms of responsibilities and allocation of each discipline/trade during each phase as well as identifying flaws. With fully animated 4D schedules, project stakeholders can mitigate the risk of delays through re-sequencing and coordination optimization.

Architectural firm saves on construction cost and time

A UK based architectural firm partnered with TrueCADD to develop a federated BIM model with construction sequencing for a multi-storey mixed-use building.

The TrueCADD team completed the project with 4D BIM simulation using Revit® and Navisworks® in two months.

The 4D BIM model delivered along with a sequential video helped the architectural firm:

- Improve design intent communication with its customers

- Save on construction costs

- Reduce reworks substantially with sequential video

What are the types of 4D construction scheduling techniques?

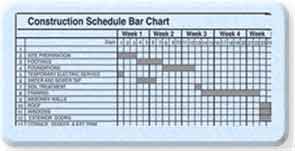

1.Bar Charts or Gantt Charts

A Bar or Gantt chart helps construction stakeholders track the status of a construction project. Bar Charts predominantly help AEC stakeholders manage the project better. A Gantt chart or Bar Chart is a significant technique or tool for project managers to schedule tasks and monitor them.

It also helps Project managers track and monitor activities until each activity gets completed as well as the people who are working on each activity. Using a bar chart, the tasks are illustrated on the Y-axis, and the time is illustrated on the X-axis.

Benefits of Bar Charts

- Manage and monitor task relationships.

- Manage job completion and update status.

- Identify issues and assign scheduling resources.

- Visualize project progress and make informed decisions.

- Simplify complex workflows and reduce delays & rework.

- Linked Bar Charts use various shapes like lines and arrows to link items and activities for every scheduled.

Disadvantages of Bar Charts

- It has been recorded that Bar charts fail to give proper results for an activity count that is greater than 30.

- Inability to create detailed tasks through a bar chart is not useful.

- Meetings or review processes are not handled by bar charts.

- May become more complex based on the project count.

- Difficult to track changes and supervise resources.

- Challenging to review on paper.

2.Critical Path Method

The Critical Path Method or CPM is used for scheduling and planning. It is represented by a network that depicts duration, sequence, and interrelation of activities.

CPM can identify the entire track or chain of tasks or activities. During the initial stages of a project, the number of activities and costs might be high. But as the project moves forward, CPM uses various algorithms to sort out into routine.

There are various CPM schedules such as Feasibility Studies, Presentation, Budgeting, Milestone, Baseline, etc. that project managers can leverage. By using CPM through Primavera, Microsoft Project, etc., project managers can identify time and float in the project.

Resource utilization can be optimized using the Critical Path Method through abbreviations like ES or Early Start, EF or Early Finish, LS or Late Start, LF or Late Finish, D or Duration, TF, or Total Float.

Benefits of CPM

- Better representation of development work.

- Accurate planning and effective task or activities arrangement.

- Defines important tasks.

- Saves time and manages deadlines.

- Compare planned and real status.

- Identify critical activities.

Disadvantages of CPM

- CPM for large projects becomes complex, difficult and ineffective if not well-defined.

- Unable to handle sudden changes.

- Resource allocation is not monitored accurately.

- Difficult to estimate activity completion for multi-dimensional projects.

READ HERE : Benefits of 4D & 5D BIM to Construction Projects

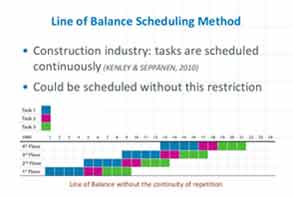

3.Line of Balance Sequencing

The Line of Balance Sequencing is a series of inclined lines that depict the rate of working between repetitive operations. It is also called as “Repetitive Scheduling Method” or RSM. Line of Balance Sequencing is best used for high-rise buildings, horizontal BIM infrastructure like highways, railways, pipelines, etc.

A-Line of Balance (LOB) is a technique that depicts repetitive tasks or work that exists in a project as a single line on a graph. In simple words, the LOB chart shows the rate at which work for all activities needs to be done to stay on schedule and the relationship between various trades or processes is defined by spaced lines.

Benefits of LOB

- Shows and optimize resources used for repetitive activities.

- Faster time and cost optimization analysis for each activity.

- Offers better visualization and presentation assuring better management of project sub-contractors.

- Quicker to modify, change, and update.

Disadvantages of LOB

- Inability to generate a clear CPM of the project schedule.

- Cannot divide the project in terms of trades, users can only divide it by location.

- Does not include productivity rates, or the complete effect of learning curves, crews, or any changes in resources.

4.Q-Scheduling

Q-Scheduling is defined as Quantitative Scheduling wherein quantities to be scheduled or executed at different locations of the construction project are used to form the elements of a schedule.

With Q-Scheduling, project managers can extract quantities from various project locations and make the model move closer to real-time. It helps schedulers determine cost and relationship through a sequence of performed tasks.

In simplicity, it is the only technique that can form a relationship between a sequence of performing a task and cost to be incurred for it.

Benefits of QS

- Indicates relationship between tasks sequences and costs.

- Suitable for different volumes of repetitive activities at different locations.

Disadvantages of QS

- A relatively new technique that hasn’t received significant traction.

- Needs a lot of resources to establish task schedules.

Conclusion

All-in-all, it has become apparent that 4D BIM is a complete game-changer for the AEC industry. The potential to visualize detailed depiction of project progress is extremely robust. This saves the sector valuable time and keeps the projects within the budget. A solid understanding of its function and scheduling techniques can help a project team make the most out of its application. It also gives project owners a clear and complete visual on how a site would appear without any curiosity or disappointment.

4D BIM also offers project stakeholders greater opportunities and benefits in terms of time-related information based on interdependencies, lead time, construction and on-site installation. On-site rework and material waste reduces saving on time and cost.

With BIM simulations helping stakeholders focus on spatial and workflow clashes, more and more project stakeholders are adopting 4D Scheduling to implement project prototypes.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.