Design automation tools like SolidWorks and DriveWorks help metal fabricators reduce manufacturing costs by streamlining design processes, minimizing material waste, and improving accuracy. By automating repetitive tasks and enhancing communication between teams, these tools cut labor costs and speed up production, making metal fabrication more efficient and cost-effective.

info@truecadd.com

How Design Automation helps Metal Fabricators Reduce Manufacturing Costs

Table of Contents

- What is Design Automation in Metal Fabrication?

- Benefits of Design Automation for Metal Fabricators

- How Design Automation for Metal Fabricators Contributes to Reducing Manufacturing Costs

- Pain Points for Metal Fabricators When Adopting Customization

- Overcoming Common Challenges in Implementing Design Automation for Metal Fabricators

- The Future of Design Automation in Metal Fabrication

- Conclusion

Design Automation for metal fabricators is transforming how they operate, providing a strategic advantage against escalating manufacturing costs. Automating repetitive design tasks helps metal fabricators reduce errors and streamline workflows. This enhanced efficiency in metal fabrication processes translates to faster turnaround times and optimized material usage, leading to substantial cost savings.

The benefits of design automation in metal fabrication, powered by SolidWorks and DriveWorks, extend beyond cost reduction. They allow fabricators to explore more design iterations, facilitating innovation and improving product quality. These tools also free up valuable time to focus on complex projects and strategic initiatives.

Embracing cost-saving techniques in metal manufacturing is crucial to gaining a competitive edge. Design automation empowers metal fabricators to achieve greater efficiency, reduce waste and ultimately enhance their bottom line.

What is Design Automation in Metal Fabrication?

Design automation refers to the use of advanced software systems to automate repetitive design tasks in the manufacturing process. It replaces the need for manual input, allowing fabricators to rapidly develop designs that can be directly translated into production. Tools like SolidWorks, a popular CAD solution, and DriveWorks, an automation software that works seamlessly with SolidWorks, are widely used in the industry.

SolidWorks allows engineers to create precise 3D models of metal parts, while DriveWorks automates the creation of custom products based on design rules. This combination significantly speeds up the design process and ensures consistency across projects. By using these tools, metal fabricators can streamline their entire workflow, improving the speed, accuracy, and consistency of their manufacturing processes.

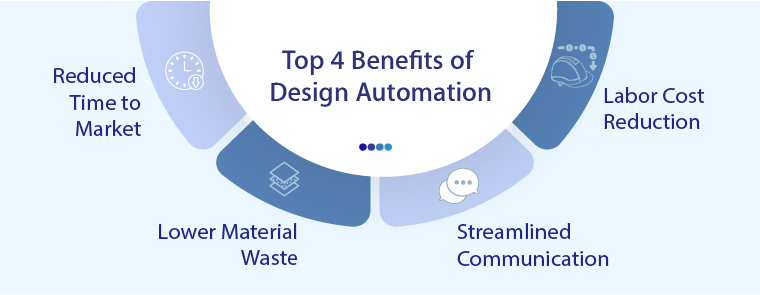

Benefits of Design Automation for Metal Fabricators

Design automation in metal fabrication offers numerous benefits to fabricators, revolutionizing their processes and enhancing their overall efficiency and productivity.

The following are some of the key advantages:

Reduced Time to Market

One of the most significant benefits of design automation is the reduction in time to market. Traditional fabrication processes often require extensive manual design modifications, which can slow down production. With automated design tools like SolidWorks and DriveWorks, metal fabricators can make real-time modifications to their designs, dramatically speeding up the production cycle.

For instance, DriveWorks enables the automation of repetitive tasks by creating multiple variations of a design with just a few inputs, saving valuable time on custom fabrication projects. This reduces project lead times and ensures that products reach the market faster, a critical factor for custom fabrication projects with tight deadlines.

Lower Material Waste

Precision is crucial in metal fabrication, as even minor errors can result in significant material waste. With design automation tools like SolidWorks, fabricators can significantly reduce material waste by optimizing the cutting and shaping of metal components. The precision of CAD models ensures that the right amount of material is used with minimal scrap.

Moreover, DriveWorks enhances this by ensuring that every custom variation of a product is produced with optimal material efficiency. By reducing waste, fabricators not only lower costs but also contribute to more sustainable production practices.

Streamlined Communication between Design and Production Teams

In metal fabrication, miscommunication between design and production teams leads to costly errors and project delays. Design automation tools like SolidWorks address this challenge by directly integrating design data into the production process. This empowers both teams to work from a unified platform with real-time updates, promoting collaboration and reducing errors.

Integrating DriveWorks further enhances this capability by automating the transition from design to production. DriveWorks automatically generates the necessary manufacturing data, such as CAD models, BOMs and drawings, ensuring that the design intent is accurately translated into production. This streamlined process minimizes errors, reduces rework, and speeds up time-to-market, ultimately improving overall efficiency and profitability.

Labor Cost Reduction and Skill Gap Bridging

As manufacturing becomes more complex, the demand for skilled labor increases. However, design automation tools like DriveWorks help bridge this gap by simplifying the fabrication process. DriveWorks can be set up with design rules that allow less-skilled workers to manage custom design tasks without needing advanced CAD expertise. This reduces the reliance on highly specialized labor and cuts labor costs.

Furthermore, SolidWorks is known for its intuitive interface, making it easier for employees to learn and use. Together, these tools lower the barriers to adopting advanced manufacturing techniques, enabling fabricators to produce complex products without the need for extensive training or expertise.

How Design Automation for Metal Fabricators Contributes to Reducing Manufacturing Costs

Automation of Repetitive Design Tasks

In traditional manufacturing, repetitive design tasks can be time-consuming and labor-intensive. Design automation tools like DriveWorks allow metal fabricators to automate these tasks, significantly reducing the time and cost involved. Tasks like the creation of shop drawings, nesting layouts, and CNC programs, which typically require extensive manual input, can now be automated. For instance, designs that are frequently used, such as brackets or frames, can be stored in a DriveWorks database and automatically generated with minimal manual effort.

By automating routine processes, companies can drastically reduce lead times, lower production costs, and allow designers to focus on more complex tasks. Parameterized models enable quick modifications of variables like dimensions and material thickness without needing to redraw entire parts, saving time and improving efficiency. Additionally, automation extends to CNC code generation directly from design files, ensuring consistency and reducing errors, further enhancing overall productivity.

Success Story: Table Configurator for Stainless Steel Furniture Manufacturer in UK

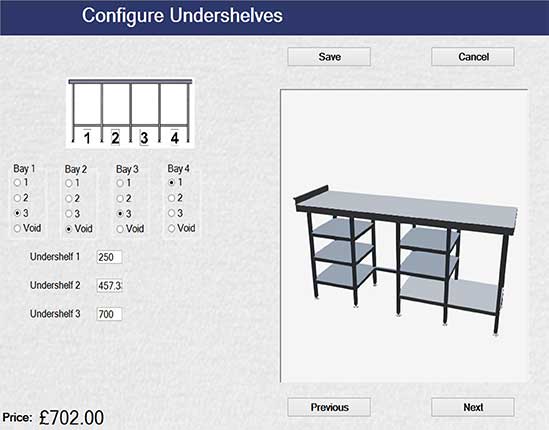

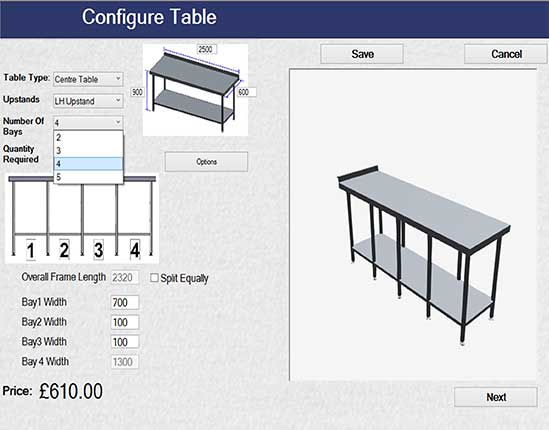

TrueCADD developed a custom DriveWorks-based online table configurator for a stainless steel furniture manufacturer in the UK. The configurator allowed the client to automate the creation of custom table designs and manufacturing drawings, reducing manual efforts, and improving design accuracy.

Key benefits achieved:

- Automated creation of 3D CAD models and manufacturing drawings

- Enhanced design flexibility with customizable options

- Streamlined design-to-production process through DriveWorks integration

Table Undershelf Configuration

Table Undershelf Configuration

CAD Configurator for Stainless steel table

CAD Configurator for Stainless steel table

Eliminate repetitive tasks and reduce total fabrication costs.

Contact our automation experts »Cost Savings through Improved Accuracy

Integrating design automation software like DriveWorks with a parametric 3D CAD platform like SolidWorks reduces costs through enhanced accuracy. By capturing your design rules and logic within SolidWorks, DriveWorks empowers you to generate error-free manufacturing drawings and CNC files directly from sales configurations or design variations. This ultimately helps you with your CNC machining cost reduction strategies. Using CAD software for metal fabrication efficiency thus eliminates time-consuming and error-prone manual data reentry, a major cost driver in traditional workflows.

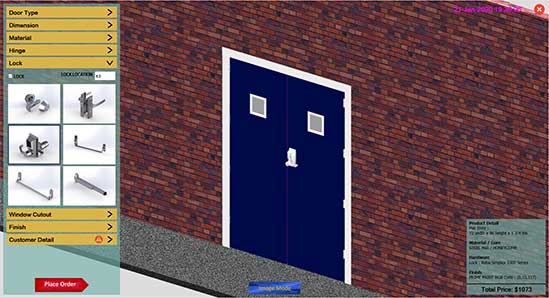

Consider the challenges faced by a sheet metal door manufacturer. Each customer order often presents a unique set of dimensions, material specifications and hardware requirements. Translating these variables into shop floor-ready deliverables manually invites dimensional errors, material waste, and costly reworks. DriveWorks helps by automatically generating precise flat patterns, bend deductions, and cut lists based on your configured parameters.

Success Story: Door Configurator for Metal Doors and Frame Manufacturer

TrueCADD implemented DriveWorks to create a custom door configurator for a hollow metal door manufacturer. This automation reduced design cycle time by 70%, delivering tailored 3D CAD models and manufacturing drawings for various door components.

Key Results:

- Automated custom door frame design

- Reduced manual design effort by 70%

- Delivered precise 3D models and manufacturing-ready drawings

Online Configurator for Metal Door

Online Configurator for Metal Door

3D Door Components Customization

3D Door Components Customization

Optimized Supply Chain Management

Another way design automation helps metal fabricators reduce costs is by optimizing supply chain management. With automated design systems like SolidWorks and DriveWorks, you get precise material requirements for every project, ensuring you order the right amount every time. This means reduced excess inventory and less waste, allowing you to optimize your resources and manage costs.

DriveWorks also brings predictability to your production schedule. This leads to faster design cycles, reduced errors and optimized material usage. DriveWorks also facilitates better communication between design and manufacturing teams, ensuring that everyone is working with the same up-to-date information. Ultimately, this gives you a more agile and efficient supply chain.

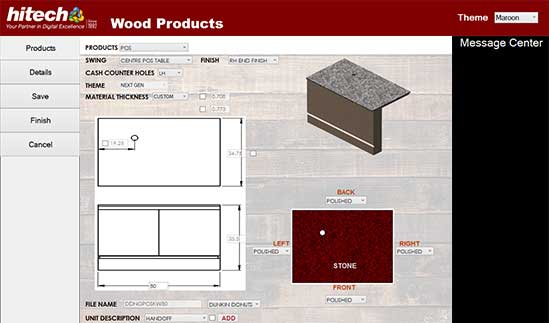

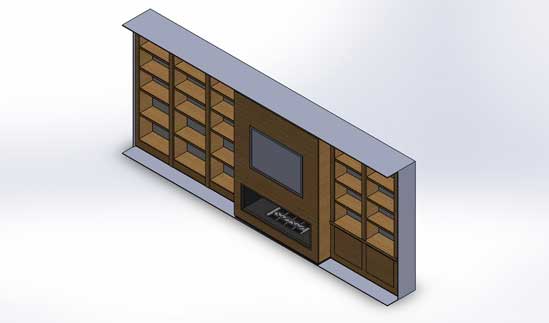

Success Story: DriveWorks Design Automation for Metal & Wood Furniture Manufacturer

TrueCADD successfully reduced lead times for a USA-based metal and wood furniture manufacturer by implementing DriveWorks design automation. This enabled efficient CAD configurators, improving the customization process for furniture products, especially kitchens.

Key Results:

- Streamlined CAD customization for metal and wood products

- Automated 3D model generation for kitchen assemblies

- Enhanced product configurators for improved design flexibility

DriveWorks Configurator for wood furniture products

DriveWorks Configurator for wood furniture products

Automated CAD Design for Kitchen Furniture

Automated CAD Design for Kitchen Furniture

Simplify repetitive design tasks with sheet metal automation tools.

Get started today »Pain Points for Metal Fabricators When Adopting Customization

Customization is a critical demand in modern manufacturing, but it introduces several pain points for metal fabricators. Here are some common complaints we hear from clients about customization:

“Our design teams take forever to create drawings. And without updated drawings on the shop floor, project timelines keep getting pushed ahead. Even after investing several hours, design errors still remain.”

– Global Design Head, Retail Store Furniture Manufacturer, Europe.“My sales team is out in the field selling products that my shop floor can’t manufacture. Fixing this takes another week, and the customer is disappointed!”

– Project Engineer, Tank Manufacturer, USA.

“Every customer wants a different kitchen look. Calculating costs for customized products is crazy. We can’t share accurate quotes at such short notice!”

– Project Manager, Hydraulics Equipment Manufacturer, Australia.These examples highlight common issues such as delays in design, miscommunication between sales and production teams, and difficulties in cost estimation for customized products. These pain points not only slow down operations but also impact customer satisfaction and overall profitability.

How you can save 100’s of design hours with product configurators.

Find out how »Overcoming Common Challenges in Implementing Design Automation for Metal Fabricators

Initial Investment Costs

Implementing design automation often involves a substantial up-front investment in software and equipment. CAD systems like SolidWorks and DriveWorks, plus the necessary hardware, represent a significant cost. However, many metal fabricators have discovered that the long-term return on investment (ROI) outweighs the initial expense.

Design automation enables you to improve efficiency, reduce material waste, and lower labor costs. This translates into a system that can often pay for itself within a few years. Before making any investment, carefully assess your specific needs and weigh the potential savings against the upfront costs.

Learning Curve and Skill Requirements

Adopting new design automation tools can be challenging due to the learning curve involved. Employees may need training to effectively use SolidWorks and DriveWorks. However, both tools prioritize user-friendliness, promoting a quicker and more intuitive learning process.

DriveWorks allows the creation of customized interfaces, enabling users without CAD experience to configure and manage products easily. Training resources provided by software vendors can equip fabricators and their employees with the proficiency needed to use these tools.

The Future of Design Automation in Metal Fabrication

As technology continues to advance, the future of design automation in metal fabrication looks promising. Emerging technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are expected to play a significant role in enhancing automation in the coming years.

DriveWorks and SolidWorks are already laying the groundwork for these advancements. AI-powered automation tools will allow fabricators to predict and prevent potential errors before they occur, further reducing costs and improving efficiency. Additionally, the rise of Industry 4.0, which integrates smart manufacturing systems, will enable metal fabricators to optimize their operations and stay ahead of the competition.

Frequently Asked Questions (FAQs)

-

Design automation is the strategic implementation of software systems, such as SolidWorks and DriveWorks, to streamline repetitive design tasks in metal fabrication. By automating these processes, fabricators achieve reductions in design time, enhance accuracy, minimize waste, and ultimately lower labor costs.

-

The financial benefits of design automation vary depending on the extent of implementation. However, companies typically experience a reduction in production costs ranging from 20% to 30% by leveraging tools like SolidWorks and DriveWorks.

-

For CAD design, SolidWorks is a widely adopted and powerful solution. To automate the design of custom products, DriveWorks excels. These tools integrate seamlessly, establishing an efficient workflow from design to production.

Conclusion

Design automation tools like SolidWorks and DriveWorks offer a wide range of benefits for metal fabricators, from reducing time to market and material waste to lowering labor costs and improving overall production efficiency. By adopting these tools, fabricators can significantly reduce manufacturing costs and enhance their competitive edge.

As the industry continues to evolve, the role of automation in metal fabrication will only grow, making it an essential tool for fabricators looking to stay ahead in the market. Now is the time to explore design automation tools like SolidWorks and DriveWorks and harness their potential to drive cost savings and operational excellence.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.