Material estimation process for millwork keeps projects within budget through detailed calculation of materials and labor costs, factoring in overhead expenses. Outsourcing estimation offers efficiency, reliability, and helps overcome challenges through advanced tools, thorough evaluation processes and expert collaboration.

info@truecadd.com

Material Estimation Process for Millwork: A Contractor’s Guide

Table of Contents

- What is Millwork and Why is Accurate Material Estimation Important?

- Key Steps in the Millwork Material Estimation Process

- Benefits of Outsourcing Millwork Material Estimation Services

- Overcoming Common Challenges in Material Estimation

- Why Choose Our Company’s Millwork Estimation Services?

- Conclusion

For small and medium millwork contractors, precise material estimation is crucial for successful bidding. Accurate estimates keep projects within budget, minimize waste, and maintain high quality standards. This guide equips contractors with a comprehensive understanding of the millwork material estimation process, highlighting key points and offering insights into best practices.

What is Millwork and Why is Accurate Material Estimation Important?

Millwork covers custom-made woodwork and architectural elements like cabinetry, moldings, trim, and more. Accurate material estimation is essential for several reasons:

- Budgeting Precision: Accurate estimates ensure that financial planning aligns with project costs, preventing overruns. This includes accounting for materials, labor and overhead.

- Material Optimization: Reduces waste by ordering the exact amounts needed, promoting sustainability and cost-efficiency. By precisely calculating the necessary materials, contractors can minimize waste, which is not only cost-effective but also environmentally friendly.

- Quality Assurance: Helps select appropriate materials, ensuring superior craftsmanship. Accurate estimation allows for the selection of the right quality and quantity of materials, which directly impacts the durability and aesthetics of the millwork.

- Project Efficiency: Avoids delays caused by material shortages or miscalculations, leading to smoother project timelines. Proper estimation ensures that all required materials are available when needed, preventing work stoppages and ensuring that the project stays on schedule.

Key Steps in the Millwork Material Estimation Process

1. Understanding Project Requirements

The first step in any estimation process is to understand the project requirements thoroughly. This involves reviewing architectural drawings, blueprints and any other project specifications. Detailed project requirements help align the goals of the project with the client’s expectations and available resources. This step is crucial for ensuring that the estimate is tailored to meet the specific needs of the project.

2. Calculating Material Requirements

Once the measurements are taken, the next step is to calculate the material requirements. This involves developing a comprehensive list of all materials needed, including specific types of wood, hardware, adhesives and finishes. Each material’s quantity and dimensions should be clearly outlined. It’s also important to include a waste factor, typically an additional 5-10%, to account for cutting errors and material imperfections.

3. Labor Cost Estimation

Estimating labor costs involves assessing the total number of labor hours required for the project. This should take into account the complexity of the millwork, which influences how much time skilled carpenters will need. Using historical data from similar past projects and expert input can provide a more accurate labor estimate. Additionally, local labor rates and regulations should be considered.

Simplify material planning for your millwork project with our expert estimates.

Get a quote »4. Accounting for Overhead and Additional Costs

Overhead costs include equipment depreciation, storage fees, transportation and facility-related expenses. It’s important to consider all these costs to develop a realistic and comprehensive budget. Additional expenses such as special tool rentals, safety measures, and compliance with local regulations should also be factored in.

5. Final Cost Consultation

The final step is to compile all the estimated costs, including materials, labor, overhead and a markup for profit. This comprehensive cost analysis ensures that the project is financially viable and helps in setting a realistic budget. It also provides a basis for negotiations with clients and subcontractors.

Benefits of Outsourcing Millwork Material Estimation Services

Outsourcing millwork material estimation services offers several advantages:

- Expertise: Professionals bring specialized knowledge and improve estimate accuracy. Their experience with various types of projects allows them to foresee potential issues and plan accordingly.

- Efficiency: Saves time and resources by leveraging experienced estimators. Professionals can quickly and accurately assess project needs, reducing the time spent on estimation and allowing the project to proceed more smoothly.

- Reliability: Reduces the risk of errors and unforeseen costs, ensuring projects run smoothly. Professional estimators use advanced tools and methods to provide reliable estimates, which helps in maintaining project timelines and budgets

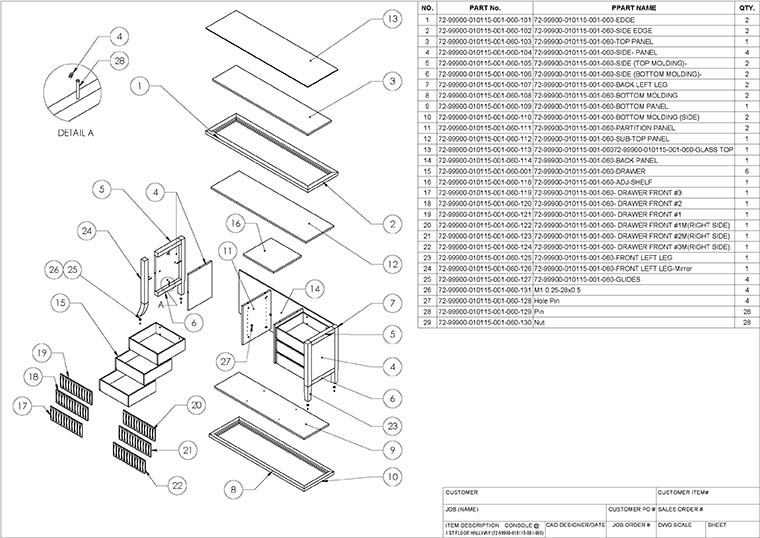

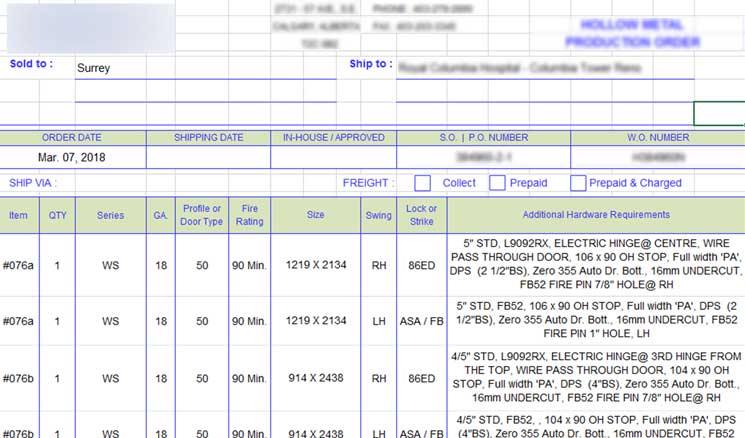

Material estimates enabled manufacturers of door and frames to estimate costs accurately

TrueCADD provided detailed material takeoffs for a Canadian manufacturer of wooden doors, frames, windows, and hardware. Leveraging architectural 2D drawings and door-window schedules, the team delivered comprehensive excel files with material estimates. These estimates enabled the client to accurately predict material requirements and associated costs, optimizing their manufacturing processes and resource allocation.

Material Estimates Manufacturer Door Frames

Material Estimates Manufacturer Door Frames

Optimize your millwork project workflow with precise quantity takeoffs.

Find out more »Overcoming Common Challenges in Material Estimation

Challenges like inaccurate measurements, material wastage, and unforeseen site conditions can disrupt projects. Overcoming these involves:

- Advanced Tools and Technology: Using digital tools for precise measurements and material tracking can significantly reduce errors. Tools like 3D modeling software, laser measures, and project management software help in obtaining accurate measurements and visualizing the project before execution.

- Detailed Planning: Thorough planning and reviewing project requirements can help in anticipating challenges. This includes regular consultations with clients and revisiting project specifications to ensure all details are accounted for.

- Continuous Evaluation: Regularly updating estimates based on real-time data and site conditions helps maintain accuracy. This includes adjusting for any changes in the project scope or unforeseen site conditions.

Why Choose Our Company’s Millwork Estimation Services?

Our company specializes in delivering precise and detailed millwork estimates, ensuring projects are completed on time and within budget. Our services include:

- Comprehensive Assessments: We conduct thorough reviews of project requirements, site conditions, and material needs. This detailed approach ensures that all aspects of the project are considered, leading to more accurate estimates.

- Expert Collaboration: Our team collaborates with skilled craftsmen and uses advanced technology for accurate estimates. By leveraging the expertise of experienced professionals and using the latest tools, we ensure that our estimates are reliable and comprehensive.

- Commitment to Quality: We prioritize high standards in every aspect of our work, ensuring superior results for our clients. Our commitment to quality means that we use the best materials and employ meticulous attention to detail in our estimation process.

Conclusion

Accurate material estimation is the backbone of successful millwork projects. By following best practices and leveraging professional services, contractors can ensure their projects are efficiently managed, cost-effective, and of the highest quality.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.