Microvellum streamlines custom millwork projects through advanced parametric design and automation capabilities. Microvellum shop drawings use 3D modeling and integrated reporting tools to enhance precision while reducing errors and waste.

info@truecadd.com

How Microvellum Shop Drawings Improve Custom Millwork Projects

Table of Contents

- Enhancing custom millwork with Microvellum shop drawings

- Using Microvellum features to optimize millwork drawings for efficiency

- Overcoming custom millwork detailing challenges with Microvellum

- Microvellum integration for custom millwork project management

- Using Microvellum shop drawings for installation and quality control in millwork projects

- Wrapping Up

Microvellum shop drawings help to greatly improve and streamline the creation of custom millwork project drawings through advanced parametric design capabilities and technical documentation. Key Microvellum features include its integrated approach, combining accurate measurements, 3D visualization tools, and automated cutting lists to streamline the entire design-to-fabrication process.

By centralizing project data and enabling real-time collaboration, Microvellum reduces design cycle times. The system’s extensive library of pre-defined components, coupled with customization features, allows designers to rapidly develop detailed millwork shop drawings that meet exact client specifications.

Enhancing Custom Millwork with Microvellum Shop Drawings

Microvellum shop drawings provide you with the tools and information needed to enhance your custom millwork project. Here’s how they empower you:

A. Benefits in Custom Millwork Project Operations

When evaluating custom millwork projects, understanding the role of Microvellum shop drawings is essential. These drawings provide a comprehensive technical foundation for the project, impacting communication, manufacturing, and quality control.

Communication and collaboration

- Understand every detail: Access drawings with precise dimensions and 3D visualizations, allowing you to fully grasp the project and communicate effectively with your team, regardless of location.

- Collaborate remotely: Review and approve designs from anywhere, ensuring you’re always in the loop and can provide feedback efficiently.

Manufacturing efficiency

- Ensure precision: Benefit from accurate manufacturing through direct integration with CNC machinery, saving time and costs.

- Support sustainability: Contribute to an environmentally conscious project with optimized material usage that minimizes waste.

Quality control

- Minimize errors: Precise drawings minimize errors, resulting in high-quality millwork that meets your exact specifications.

- Better prefabrication: Enjoy faster on-site installation and superior quality control thanks to detailed drawings that enable prefabrication.

B. Leveraging Parametric Modeling

Microvellum utilizes parametric modeling, interconnecting all elements. This means that adjusting one dimension automatically updates all related components. For instance, when designing a cabinet with multiple drawers, changing the drawer height in Microvellum automatically repositions all related components.

This ensures precision drafting and eliminates manual adjustments, minimizing errors and ensuring every detail is perfectly coordinated. The software also automates shop drawing generation, reducing the risk of human error and ensuring precise fabrication documentation.

C. Design Customization

Microvellum empowers designers with extensive customization options, offering unparalleled flexibility for bespoke furniture millwork projects. This millwork shop drawing software provides vast libraries of pre-built components for the quick assembly of common elements. You can also create your own custom components and save them for future use.

However, true customization lies in the ability to create custom profiles and precisely control joinery. You can incorporate your own design rules and calculations into Microvellum. This allows you to automate complex processes and ensure that your custom designs meet specific requirements or industry standards.

D. Software Advantages

Microvellum enhances precision in millwork shop drawings through a suite of powerful features. Dynamic 3D modeling allows visualization and real-time error detection, while automated drawing generation eliminates manual drafting and reduces errors.

Integrated reporting tools provide accurate material data, and CNC machine integration streamlines production with precise machine code generated directly from the design. These software advantages combine to increase accuracy, minimize errors and boost millwork production efficiency.

Elevate your designs with high-quality Microvellum shop drawings.

Learn more →Cabinet Drafting Solutions for Custom Residential Furniture, USA

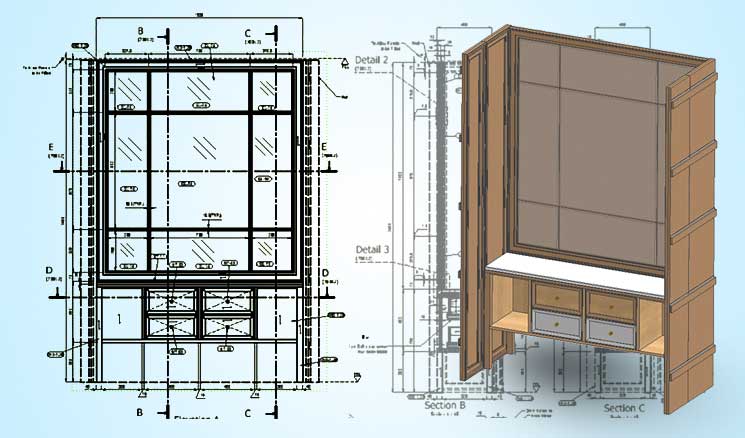

A USA-based residential furniture manufacturer required precise cabinet CAD drafting services to enhance their production efficiency. They sought to outsource this task to achieve faster turnaround times and maintain high-quality standards.

TrueCADD was tasked with converting architect’s PDFs and marked-up drawings into detailed CAD models and drawings. The scope included creating bespoke furniture designs, such as library units, ensuring accuracy and adherence to the client’s specifications.

The final deliverables led to:

- A 50% reduction in turnaround time for cabinet drafting tasks

- Enhanced production efficiency due to precise and detailed CAD drawings

- Improved ability to meet client demands with high-quality, customized furniture designs

Cabinet CAD Drafting for Residential Furniture

Cabinet CAD Drafting for Residential Furniture

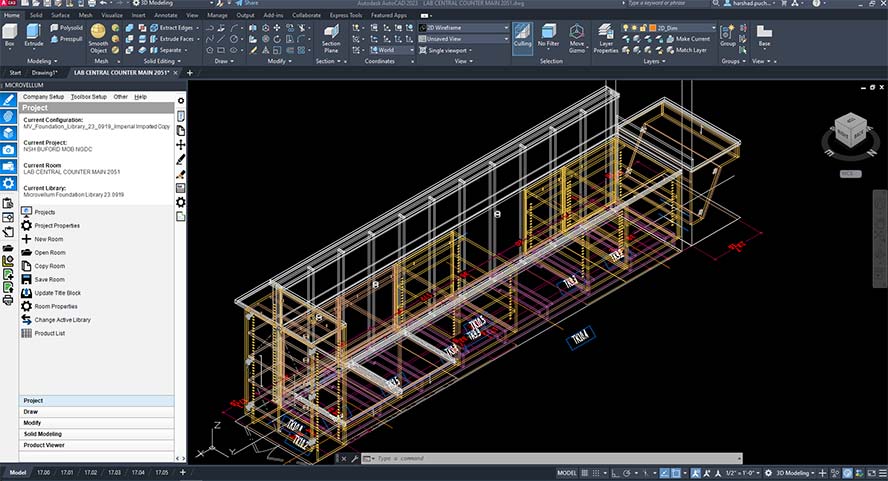

Using Microvellum Features to Optimize Millwork Drawings for Efficiency

Microvellum for Woodwork Design Drafting

Microvellum for Woodwork Design Drafting

Microvellum offers features specifically designed to streamline the creation of shop drawings and boost overall production efficiency. Here’s how:

-

Parametric arrays and dynamic components:

Consider designing a wall with repeating panels. Instead of drawing each panel individually, Microvellum parametric arrays allow you to create one panel and then replicate it with specified spacing and quantities.

Similarly, dynamic components adapt to changes in real time. For example, a drawer component can be designed to automatically adjust its dimensions based on cabinet size. These features drastically reduce design time and ensure consistency across repetitive elements.

-

Organized drawings:

Microvellum promotes efficient fabrication through clear layering systems, consistent naming conventions and embedded metadata within the drawings. This detailed organization ensures that fabricators can easily interpret the design intent, locate specific components, and understand their properties without ambiguity.

-

Nesting and toolpath optimization:

Microvellum offers tools to optimize material usage and CNC machining processes. Its nesting capabilities allow users to arrange parts on sheet materials in the most efficient way, minimizing waste.

The software helps generate optimized toolpaths for CNC machines, reducing cutting time and improving the overall efficiency of the manufacturing process. This level of integration between design and manufacturing streamlines workflows and contributes to cost savings.

Save time by standardizing parts with Microvellum’s parametric libraries.

Learn more →Overcoming Custom Millwork Detailing Challenges with Microvellum

Custom millwork often involves intricate designs that push the boundaries of traditional woodworking. Microvellum equips designers with the tools to tackle these challenges confidently:

Handling Unusual Angles and Curves

Microvellum excels at accurately representing nonstandard angles and curves. Spline tools allow for the creation of smooth, flowing curves, while 3D sketching capabilities enable designers to draw complex shapes directly in a three-dimensional space.

The software’s import/export functionality allows for seamless integration with other design programs, ensuring that even the most intricate designs can be accurately translated into shop drawings.

Avoiding Non-standard Materials

Beyond traditional wood, modern millwork often incorporates unique materials like acrylics, metals, or composites. Millwork CAD software, such as Microvellum, offers extensive material libraries that include a wide range of options. Designers can also create custom materials with specific properties and grain patterns.

This ensures that shop drawings accurately reflect the chosen materials, aiding in precise fabrication and realistic visualizations.

Visualizing Complex Joinery

Complex joinery, like intricate dovetails or hidden miters, requires clear communication to ensure accurate fabrication. Microvellum allows designers to create detailed shop drawings with section views, 3D visualizations and annotations.

These features highlight critical joinery details, leaving no room for interpretation and ensuring that the final product meets the design specifications.

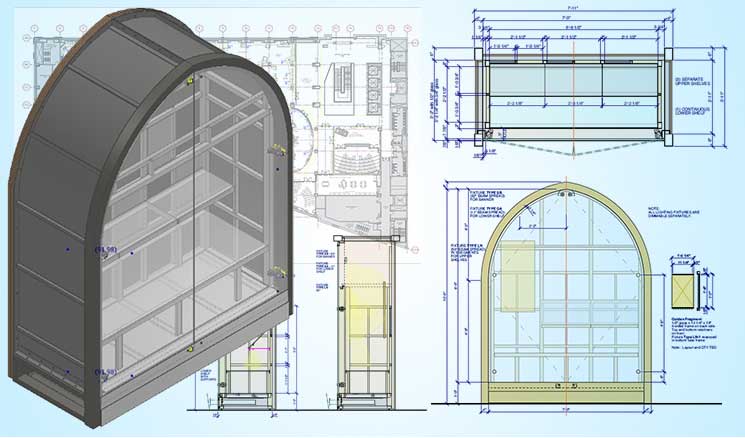

Precision Millwork Shop Drawings for Institutional Furniture, USA

An institutional furniture design and manufacturing firm in the USA required precise CAD shop drawings, along with assembly and installation guides, to streamline their production process.

TrueCADD developed detailed millwork and casework shop drawings based on the client’s architectural plans and hand sketches. These comprehensive drawings facilitated seamless communication between architects, furniture designers, contractors, and manufacturers, ensuring high-quality production with a faster turnaround time.

The final deliverables led to:

- Elimination of rework, enhancing manufacturing efficiency

- Accurate material estimation and cost savings

- Improved coordination among stakeholders, resulting in timely project completion

Millwork casework shop drawings for furniture manufacturers

Millwork casework shop drawings for furniture manufacturers

Microvellum Integration for Custom Millwork Project Management

Microvellum readily integrates with your existing business systems, including ERP software, inventory management tools, and other production applications. We achieve this integration through API connections, export/import functions, and data connectors. Connecting these systems allows data to flow seamlessly between departments, eliminating data silos and manual entry.

Consider a change order necessitating a design modification. With Microvellum integrated systems, the updated design automatically triggers adjustments in inventory orders, production schedules, and even cost estimations. This ensures everyone on the project remains informed and coordinated.

Microvellum offers a built-in report designer for customized reporting capabilities that empower project managers. Generate accurate cut lists, material orders and production schedules directly from the design data. This real-time information facilitates efficient resource allocation, material optimization, and production planning.

The software also helps track project progress, manage revisions and maintain a clear audit trail, ensuring transparency and accountability throughout the project lifecycle.

Using Microvellum Shop Drawings for Installation and Quality Control in Millwork Projects

Microvellum enhances millwork projects beyond the workshop by streamlining installations and improving quality control.

Simplifying Installation: Microvellum helps generate exploded views and step-by-step assembly instructions. These visual guides simplify installation and reduce confusion and errors. Installers can refer to 3D diagrams instead of deciphering 2D drawings. This ensures efficient and accurate installation, especially for complex units with many components.

Enhanced Quality Control: Quality control is crucial in custom millwork. Microvellum integrates quality control checklists and inspection points directly into shop drawings. These checklists remind fabricators and installers to verify critical dimensions, joinery quality, and material finishes at each stage. This systematic approach minimizes defects and ensures adherence to project specifications.

Microvellum’s annotation and dimensioning tools create comprehensive reference guides for manufacturers. These guides detail critical measurements, clearances and installation procedures. This precision minimizes rework and ensures client satisfaction.

Wrapping Up

Microvellum shop drawings have transformed how we approach custom millwork, providing a robust toolkit that increases precision, streamlines workflows and fosters better communication throughout every project. From meticulously drafted designs and personalized customizations to efficient fabrication processes and seamless project management, Microvellum equips us to deliver exceptional results.

By harnessing the software’s capabilities, we can optimize material usage, minimize errors, and consistently provide high-quality custom millwork that exceeds even the most discerning client’s expectations. As technology evolves, Microvellum leads the way, driving innovation and shaping the future of custom millwork.

Create tailored cabinets with expert Microvellum shop drawing services.

Request service →Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.