2D drawings have limited usability due to their high technical detailing. 3D CAD workflows allow industrial product designers and manufacturers to speed up design development with comprehensive design information and a single source of truth for all stakeholders.

info@truecadd.com

How accurate 3D CAD drawings improve product development

2D CAD drawings are the actual blueprint of the conceptualized product design. Only shop floor technicians are well-versed in interpreting them accurately. The frontline staff or customers will often struggle to interpret these technical drawings and therefore the usage of 2D drawings is limited to technical teams.

Given these limitations, manufacturing and design firms are increasingly moving away from traditional 2D processes and embracing 3D CAD drawings and models. 3D workflows rope in all stakeholders for product design finalization as against 2D and enable seamless communication.

3D CAD drawings allow every stakeholder to:

- Communicate design intent clearly across teams

- Visualize the concept clearly and provide feedback early

- Reduce design cycle time and save resources

- Easily access and track changes in the drawings

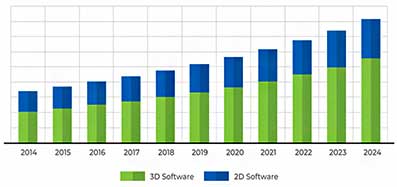

Research suggests that an increasing number of companies are adopting 3D CAD workflows as compared to 2D drawings.

But before we discuss the advantages of 3D drawings, let’s take a detailed look at where the traditional 2D process lacks and how it impacts the product development process.

Rising adoption of 3D CAD across the industry

Rising adoption of 3D CAD across the industry

Inherent Problems with 2D CAD Drawings

Ideally, while creating new product designs, a prototype is built once 2D drawings are approved. Prototypes bring all stakeholders and customers on the same page to understand design intricacies and provide inputs/feedback.

However, this, approach has two main issues:

-

Developing a product prototype often extends the design cycle time and keeps the design teams from performing other high-value tasks.

-

2D drawings are prone to interpretation errors as different stakeholders collaborate. Tracking all the design changes and controlling versions of these drawings is in itself a complex task.

Both these challenges surface once production begins. And then it may be too late to correct drawing errors without dedicating additional time for manufacturing reworks or adding to costs.

3D CAD drawings help product design firms to overcome these challenges by offering design intent and clarity in 3D space with usual 2D annotations.

5 Ways 3D CAD Drawings Improve Product Development

Whether it is a single-piece product or an assembly of several parts, 3D drawings offer easy-to-interpret design information that every stakeholder can comprehend and give feedback on. Let’s find out how it leads to improved product development.

-

Faster design cycles: Rather than making sense out of a 2D drawing, a 3D CAD drawing will enable your management and technical teams to get a crystal clear idea about how the end product will look, the features it will possess, and how it will function. This process will ensure that any design feedback that teams may have can be incorporated right from the beginning, enabling faster design cycles.

A US-based retail industry furniture manufacturer adopted 3D isometric drawings by converting and detailing the concept sketches. It enabled the manufacturer to have quicker design communication and saved 70% design costs. This was visible by a sharp decrease in number of RFIs and change orders requested by the shop floor engineers.

-

Quicker design review: Product design through 3D workflows makes it possible to produce an assembly sequence or cross-sectional design to explain the inner working of the conceptualized product. This capability allows teams to review the design faster and make critical decisions regarding part count or selecting the manufacturing process quickly and accurately.

-

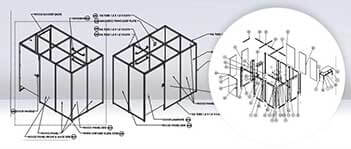

Improved inter-team communication: When designs are easy to understand, it is also possible to involve end customers in the design process and take necessary feedback from them before actual production happens. With exploded views and 3D assembly drawings, everyone involved in the product development gets a clear idea about their respective roles in bringing the concept to reality.

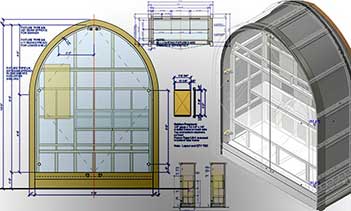

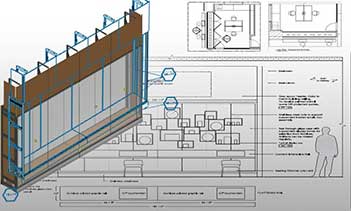

A furniture manufacturer specializing in museum quality exhibits across the USA improved design communication among designer, contractors, and manufacturing engineers using 3D CAD drawings. Detailed 3D drawings for manufacturing of cabinets and other casework offered as-is interoperation of drawings on shop floor and the frontline contracting foremen.

-

Fewer mistakes: When reviews happen during the early stages of product design, it is possible to bring down the number of errors before the design moves to production. Fewer mistakes will directly aid in bringing down the manufacturing cost. They will also prevent your workforce from spending unnecessary time reworking design drawings.

-

Leverage design automation: 3D workflows open the opportunity to take your product design process to the next level through design automation. For product designs that share similar parts and features, their new variants can be developed quickly by automating designs. The capability also allows producing accurate manufacturing drawings for each of the different variants of your product, enabling you to bring your products to market faster.

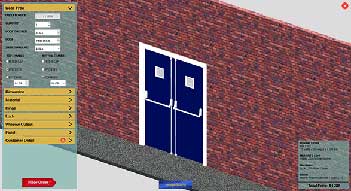

A hollow metal door and frame manufacturer based in the US accelerated engineering lead time by 70% for custom door manufacturing by using DriveWorks design automation. While a retail furniture manufacturer in the Europe for a fast-food store automated manufacturing drawings generation meeting 99.9% quality standards despite heavy design customization.

What’s next for 3D CAD drawing?

The detail-rich nature of 3D drawings positions them better for tapping into the future technologies of Industry 4.0 and direct digital manufacturing. When CAD drawings are created directly from 3D solid models, they can be used to create CNC files for machines with data connectivity. Additionally, neutral file formats like IGES/STEP ensure seamless design data exchange between cross-functional teams.

Today, manufacturers also leverage advanced AR/VR enabled tools to explain complex design intent to potential customers. AR devices when focused on light-weight 3D CAD drawings can augment the product in 3D. It increases customer interaction and ensures clear design communication.

Choose 3D CAD Drawings for Your Next Product Design and Development

2D drawings are critical in a product design and have been in the industry for a long time; however, these drawings do nothing more than providing technical details for manufacturing. They’re often difficult for non-technical teams end up with loss of resources, time, and revenue.

3D CAD drawings developed using 3D design workflows give an objective view of the conceptualized product and facilitate seamless production. A drawing or model in 3D is the key to success when it comes to establishing a robust product design. If the idea of starting your product design in 3D doesn’t convince you yet, speak with one of our engineers and get valuable insights on how 3D workflows can improve your product development process.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.