Design automation transforms custom metal fabrication by eliminating repetitive tasks, streamlining workflows, and enhancing collaboration. Using tools like DriveWorks and CAD macros reduce errors, cut design time, and improve customer responsiveness.

info@truecadd.com

How design automation improves the efficiency of custom metal fabricators

Table of Contents

- Challenges in custom metal fabrication without design automation

- What is design automation?

- Lead time challenges requiring design automation

- Benefits of design automation for custom metal fabricators

- Steps to implement design automation

- How design automation resolves custom metal fabrication challenges

- Streamlining collaboration across teams with design automation

- Future of design automation in metal fabrication

- Conclusion

- FAQs

In custom metal fabrication, coordination between sales and manufacturing teams often creates bottlenecks that extend lead times. The traditional approach involves multiple iterations and approval cycles, hampering productivity and customer satisfaction.

Design automation for custom metal fabricators transforms this process by implementing logical, rule-based systems that streamline product customization workflows. Design automation using DriveWorks and CAD macros help fabricators eliminate repetitive design tasks, automate approvals, and generate accurate manufacturing documentation instantly.

The impact is substantial: shortened quote response times, reduced engineering hours, minimized errors, and enhanced collaboration across departments. For metal fabricators producing custom components for furniture, architectural elements, or industrial equipment, automation creates a seamless path from customer specifications to the production floor, significantly boosting operational efficiency in custom metal fabrication while maintaining quality standards.

Challenges in custom metal fabrication without design automation

- Repetitive design tasks: Engineers spend most of their time recreating similar features across different products, leading to inefficiency and designer burnout.

- Inconsistent specifications: Communication gaps between sales and engineering teams result in misinterpreted requirements and costly design revisions.

- Quote response delays: Traditional RFQ processes require extensive manual calculations, extending response times to days or weeks in competitive bidding scenarios.

- Design errors: Manual design processes introduce human error, particularly in complex sheet metal components with numerous features and tight tolerances.

- Manufacturing documentation: Creating comprehensive fabrication documents, flat patterns, and DXF files manually consumes significant engineering resources.

- Configuration management: Tracking numerous product variations and ensuring manufacturing feasibility for each configuration creates logistical challenges.

What is design automation?

Design automation refers to the implementation of software tools and systems that streamline repetitive engineering tasks in the product development process. For metal fabricators, this technology transforms manual design workflows into rule-based automated processes that maintain design intent while eliminating time-consuming repetition.

The most effective design automation solutions for custom metal fabrication include:

CAD macros and scripts

Built into platforms like SolidWorks, Inventor, Creo, and AutoCAD, these tools allow designers to record sequences of commands for features like holes, bends and corner treatments. Once programed, these macros execute complex operations with a single click, maintaining consistency across similar components.

DriveWorks

This specialized automation platform integrates with CAD systems to create comprehensive automation frameworks. DriveWorks captures design knowledge and engineering rules to automatically generate 3D models, 2D drawings, BOMs and manufacturing documentation based on input parameters. Its CPQ (Configure, Price, and Quote) systems connect directly to business systems like ERP and CRM.

To explore the benefits of design automation for sheet metal manufacturers, let us first understand how lengthy lead times affect metal fabricators.

Lead time challenges requiring design automation

- Delayed responses to customer inquiries: About 60–80% of design time is spent in preparing initial design drafts and BOMs. It takes from days to weeks to respond to internal RFQs, finalize designs, and respond to customers.

- Conflicts and inaccurate lead-time estimation: Multiple decision makers in estimation, sales, engineering, planning and purchasing, and manufacturing teams lead to conflicting opinions and inaccurate lead-time estimation.

- Multiple design variants and unsatisfied customers: A product design can have several customizable features and the customer can mix and match any option. Even if one of the options is neglected, customers feel unsatisfactory sales.

The primary focus of metal fabrication firms is to deliver the best product design without affecting project cost and product quality. CAD macros and related advanced technology for automation have a lot to offer to sales, engineering and manufacturing divisions to help achieve this.

Benefits of design automation for custom metal fabricators

From easing the sales process to saving on project costs, custom metal product fabricators can avail of several benefits and add variety to their offerings. The benefits of design automation to fabrication firms for products like doors, windows, shelves, roofing, cabinets, panels, etc. are many. Here are some of them:

Benefits for sales teams and customers

- Configure products in minutes with real-time 3D visualization

- Generate 100% accurate quotes with strategic pricing

- Establish clear customer communication channels

- Update pricing instantly as configurations change

- Interactive product models enhance customer experience

Benefits for design-to-manufacturing teams

- Reduce ETO product cycles from weeks to days

- Cut CTO design time by 90% for products

- Eliminate repetitive modeling and verification tasks

- Capture material requirements and DFMA rules automatically

- Standardize manufacturing with precise documentation

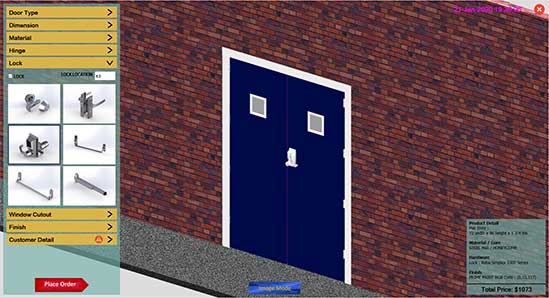

Automated Custom Metal Door &Frame Design with DriveWorks

TrueCADD developed a DriveWorks-based configurator for a U.S. hollow metal doors and frames manufacturer, automating custom design processes. This solution reduced design cycle time by 70%, delivering precise 3D CAD models and manufacturing drawings tailored to client specifications.

Online Configurator for Metal Door

Online Configurator for Metal Door

3D Door Components Customization

3D Door Components Customization

Steps to implement design automation

The following are the steps that you should follow to implement design automation

Step 1

Audit existing processes – Document current workflows, identify repetitive tasks, and calculate time spent on manual design activities to establish automation priorities.

Step 2

Define design rules – Capture tribal knowledge and engineering standards into explicit rules that can be programed into automation systems.

Step 3

Select appropriate tools – Choose between CAD macros for simpler tasks or comprehensive platforms like DriveWorks based on customization complexity and volume.

Step 4

Develop a prototype – Start with a single product family to test automation concepts before expanding to more complex configurations.

Step 5

Train design teams – Provide comprehensive training to ensure designers understand how to leverage and maintain automation tools effectively.

Step 6

Integrate with business systems – Connect design automation tools with ERP, CRM and PLM systems to create seamless information flow across departments.

How design automation resolves custom metal fabrication challenges

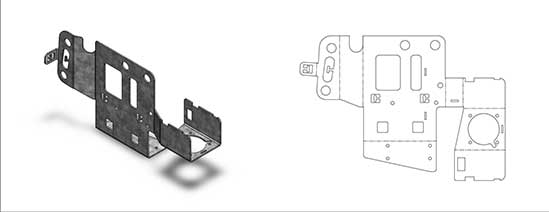

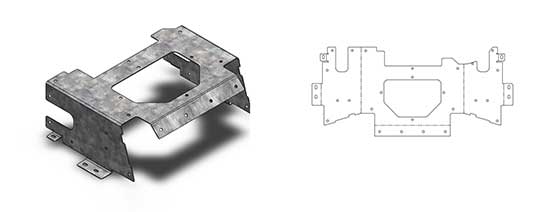

1. Automating sheet metal design with macros and scripts

When we talk about metal fabrication, it mostly encompasses sheet metal component designs and fabrication. 3D Sheet metal part design deals with features such as holes, slots, bends, notches, reliefs, etc., and most of them are repetitive. Experience says that, depending upon the complexity of the sheet metal part, it would take an hour to more than six hours to model these features, and a few more in creating detailed 2D drawings.

Clearly, without automation, it becomes a tedious job for designers, let alone the errors and time spent on QC. However, advanced CAD tools like SolidWorks, Inventor®, Creo, and AutoCAD®lifts designers’ productivity along with design quality. These CAD tools offer built-in macros and allow for creating user-friendly CAD scripting for repetitive tasks.

When CAD design automation is employed efficiently, designer can:

- Reduce more than 80% of design and detailing efforts

- Produce detailed manufacturing drawings with BOM having 100% accuracy

- Create documents and pdfs like specifications, BOMs and product images for sales and manufacturing within seconds

3D CAD users can create macros for repetitive tasks without special programming skills. All they have to do is click the record button and capture design operations that are to be replayed later.

You can find this button under Tools>Macro>Record.

Upon running a macro from the toolbar, pre-recorded operations can be repeated on the current file.

Below are some mundane tasks that macros can automate:

- Creating start part with predefined CAD environment and prefilled part parameters like material, family name, company name, thickness, coordinate systems for CAM environment

- Repeating commands for hole, slots, corner radii, fillets and features that follow patterns

- Creating a standard drawing template with title blocks, annotations, BOM table creation and item balloon location, auto view locations, lines, hatching, dimensioning, sections, etc.

- Creating flat patterns and DXF files and saving files such as BOMs and other manufacturing documents in pdf format

SolidWorks Macro Implementation Reduced DXF Generation Time by 70%

TrueCADDs’ automation engineers developed .swp files SolidWorks macros and auto-create DXF files for a sheet metal fabrication firm. Direct DXF generation from CAD models reduced lead-time from 5-7 minutes to 2 minutes and saved a few minutes in modeling each part. The firm’s design division could make time for design research and development.

Accelerate Your Design Workflow.

Get custom SolidWorks macros »2. Advanced design automation using DriveWorks

Tools like DriveWorks offer advanced design automation for complex parts and large-scale custom manufacturing. This automation platform has a range of user-friendly plug-ins to automate designs on higher levels. Additionally, DriveWorks Pro Application Program Interface has provisions for customizing the plugins for project-specific functions.

Typical tasks include:

- Developing macros for rapid feature creation

- Documentation and format conversion

- Extraction of product data into defined formats

- Search for specific parts or assembly within library

- Management of data in PLM/PDM

DriveWorks 3D Viewer allows the design engineer to view any CAD product file for enhanced collaboration. It supports all major CAD formats offered by SolidWorks, AutoCAD, Creo, SolidEdge, Inventor, etc.

The CPQ DriveApp integrates with business systems like ERP, PLM, CRM and SolidWorks to automate and increase efficiency across the value chain. This integration enables you to:

- Streamline request flow between sales [customer and sales reps], design and manufacturing

- Develop 3D visual product configurator for enhanced customer experience

- Create and manage all sales documents, including sales quotes, invoices, etc.

- Automate generation of all manufacturing documents

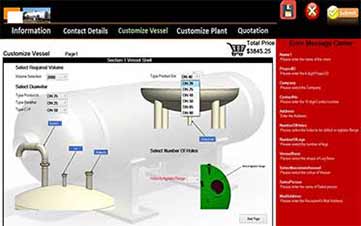

DriveWorks Configurator Transformed Pressure Vessel Manufacturing Process

TrueCADDs’ automation specialists implemented DriveWorks-based online configurator for a pressure vessel manufacturer. It streamlined and shortened the design process for metal sheets used in the pressure vessel body. The entire process, from sales to manufacturing, was automated. The client could offer higher customization and save time with a simplified communication channel.

Streamlining collaboration across teams with design automation

Design automation serves as a digital bridge connecting traditionally siloed departments within metal fabrication companies. By creating a unified platform where sales, engineering and manufacturing teams interact with the same data models, automation eliminates the communication barriers that typically slow production.

When a salesperson configures a product with a customer, the system automatically validates design feasibility against manufacturing constraints in real time. This prevents the common scenario in which sales promises features that engineering later deems impossible to produce cost-effectively.

Engineering receives complete, standardized specifications rather than ambiguous requirements, eliminating clarification loops. Meanwhile, manufacturing teams gain access to consistently formatted documentation with standardized callouts and annotations.

This collaborative ecosystem creates significant organizational benefits beyond simple time savings. Teams develop a shared technical language, cross-functional visibility improves, and the entire organization becomes more responsive to customer needs.

Future of design automation in metal fabrication

Design automation in metal fabrication is accelerating toward increasingly sophisticated systems that leverage artificial intelligence and machine learning. These technologies will transform how fabricators approach custom design by automatically analyzing historical data to suggest optimal configurations and manufacturing methods.

Cloud-based automation platforms will enable real-time collaboration between global teams and customers, allowing instant visualization and approval of complex designs from any device. This accessibility will dramatically compress decision cycles and enable 24-hour development processes.

Generative design algorithms will work within manufacturing constraints to suggest multiple fabrication-ready options that optimize cost, material usage, and performance. Meanwhile, digital twins of production equipment will enable virtual validation of manufacturability before physical production begins.

Integration between design automation and robotic fabrication systems represents perhaps the most transformative development. As these systems converge, we’ll see the emergence of fully automated workflows where customer specifications flow seamlessly from configuration to finished products with minimal human intervention, fundamentally changing the economics of custom metal fabrication.

Conclusion

Design engineers and fabricators cannot win the custom manufacturing market segment with standalone CAD tools. They are time-consuming and tedious to work with. On the other hand, design automation with macros and tools delivers faster design cycles for customized product manufacturing. It helps you make the most of your CAD system.

It requires skills and expertise to deploy design automation, as per the need and nature of your business. TrueCADD offers expertise in both DriveWorks implementation as well as custom macro creation for custom manufacturers around the world.

FAQs

-

Design automation uses software to automate the creation, modification, analysis and optimization of metal fabrication designs. It streamlines the design process, reducing manual tasks and creating a more efficient development process for engineers to work with.

-

Design automation reduces lead-time by automating repetitive design tasks. It generates drawings, models and manufacturing data (like CNC programs) faster, minimizing errors and speeding up the process from concept-to production-ready designs.

-

Popular choices include SolidWorks, AutoCAD and Inventor. The “best” depends on specific needs, but these provide robust features for 3D modeling, sheet metal design, and integrating with automation tools, such as Driveworks, effectively and efficiently.

-

Automating metal product design offers many benefits. Key advantages include reduced design time, fewer errors, improved product quality, faster quoting, increased customization capabilities and optimized material usage.

-

DriveWorks is a design automation tool that, when integrated within CAD software, allows users to create rules-based product configurators. The software automates design variations, generates manufacturing documents and streamlines the sales-to-manufacturing process.

-

Yes, automation significantly reduces errors. By using pre-defined rules and parameters minimizes manual data entry and calculations, leading to more accurate and consistent designs and a less strenuous user experience.

-

Time savings vary, but automation in general can reduce design time by half and even more in some cases. This depends on project complexity and the level of automation implemented.

-

Challenges include the initial setup cost and time. Other design automation challenges for engineers and designers include choosing the right software, training staff, adapting existing workflows and ensuring compatibility with manufacturing processes.

-

Industries such as construction, automotive, aerospace and industrial equipment manufacturing benefit greatly. Any sector requiring customized metal components with variations can leverage design automation for greater efficiency and speed.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.